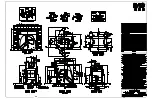

CHEMICAL INLET VALVES

1/2" Stainless steel

1/2" PVC

VALVE

24 USGPM (H2O @ 15 PSI)

30 USGPM (H2O @ 15 PSI)

FLOW RATE

The approximate full-open flow rate of this chemcial inlet valve is shown

above. At lower pressure, the flow will be reduced approximately as the

square root of the ratio obtained by dividing the actual applied pressure by

15 PSI (1ATU).

The calibrating valve can vary the flow from full-open to about 25 % of

full-open. See TABLE 1 and FIGURE 1 below for description of valve

positioning. Never use this calibrate valve to reduce the flow to less than

25% because the resultant flow will not be consistent.

Should 25% of full-flow be too great, reduce the amount of chemicals

actually injected by (1) reducing the chemical pressure, or (2) reducing the

stock chemical concentration (increasing the dilution), or (3) reducing the

time the chemical valve is commanded by the SITMIL to remain open.

(However, the valve should never be commanded to open less than about

10 seconds, because the opening and closing time of the chemical inlet

valve would become a large percentage of the injection time and thus cause

certain variations in the amount of chemical actually injected).

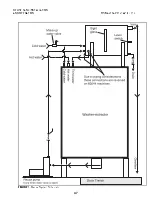

FIGURE 1

O

=90

O

=76

O

=62

O

=47

FLOW

VALVE

POSITIONING

REF.

25%

47

50%

62

75%

76

FULL

90

O

O

O

O

TABLE 1

Î

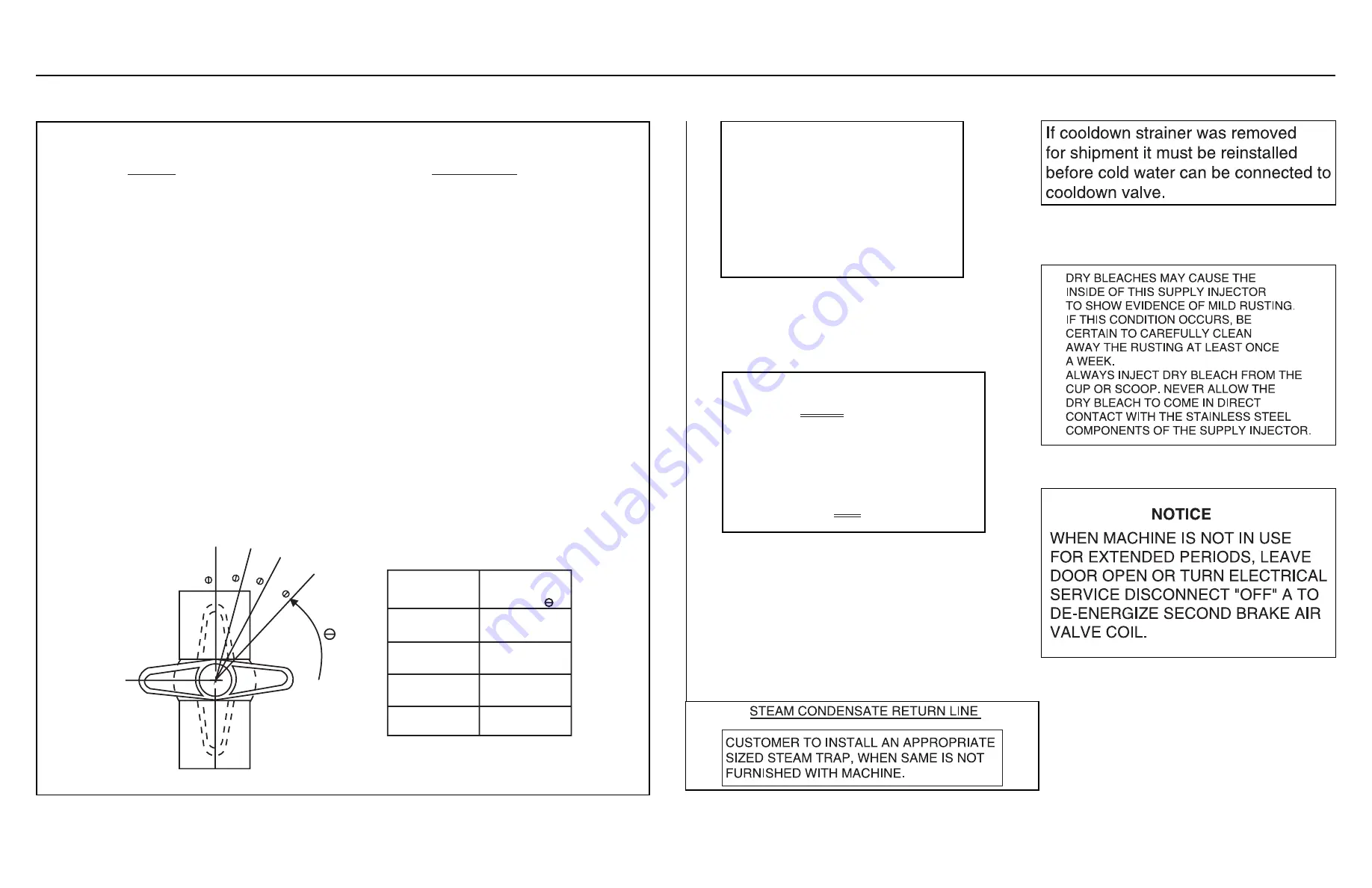

FIGURE 19

(MSIN0201BE)

Î

Central Liquid Supply Systems

WATER CONNECTION FOR:

AUTOMATIC SUPPLY INJECTOR

AND BALANCING VALVES (If

machine is so equipped).

USE HOT WATER IF IT IS AVAILABLE.

SET PRESSURE REGULATOR FOR

28 PSI WHEN THERE IS NO FLOW

OF FLUSHING OR BALANCING WATER.

Î

FIGURE 20

(MSIN0201BE)

Î

Divided Cylinder, 52" and 72"

Open Pocket Non-Tilt Machines

NOTE: CALIBRATE SUPPLIES

#1 AND #2 TWICE.

SUPPLIES #1 AND #2 HAVE TWO FLOW

RATES: NORMAL RATE FOR TIMES

A. A1, B, AND B1; HIGH RATE FOR C

AND C1. CALIBRATE BOTH #1 AND #2

AT TIME A OR B AND AT TIME C.

Î

FIGURE 21

(MSIN0201BE)

Î

Calibrating Liquid

Supply Manifold

Î

FIGURE 22

(MSIN0201BE)

Î

Cooldown/Spraydown Machines

(If applicable)

Î

FIGURE 23

(MSIN0201BE)

Î

Bleach Precaution

Î

FIGURE 24

(MSIN0201BE)

Î

Door Precaution

Î

FIGURE 25

(MSIN0201BE)

Î

Indirect Steam Condensate Return

44

Summary of Contents for 42044SR2

Page 2: ......

Page 4: ......

Page 8: ......

Page 9: ...Installation 1 5 ...

Page 37: ...Î FIGURE 8 MSIN0301AE Î Vibration Switch Î FIGURE 9 MSIN0301AE Î 60 Staph Guard 33 ...

Page 51: ...586DA4 BUecU CicdU CSXU QdYS B5EC5 D1 9 CD1 1D9 1 4 5B1D9 C9 1 15 1F _V 47 ...

Page 53: ...Dimensional Drawings 2 49 ...

Page 54: ......

Page 55: ...51 ...

Page 56: ...52 ...

Page 57: ...53 ...

Page 58: ...54 ...

Page 59: ...55 ...

Page 60: ...56 ...

Page 61: ...57 ...

Page 62: ...58 ...

Page 63: ...59 ...

Page 64: ......

Page 65: ...61 ...

Page 66: ...62 ...

Page 67: ...63 ...

Page 68: ...64 ...