Pellerin Milnor Corporation

Figure 3.

Examples of Manifolds for Chemical Tubes. Your equipment can look different.

Close the line.

If the pump does not always close the line when it is off, use a shutoff valve to do this.

Do not let a vacuum occur.

Supply a vacuum breaker in the chemical line that is higher than the full level of the tank.

Flush the chemical tube with water.

If the liquid that stays in the tube between the pump and the machine can flow in the machine,

flush the tube with water after the pump stops.

Put the chemical tube fully below the inlet.

It is also necessary that there is no pressure in the chemical tube or tank when the system is off.

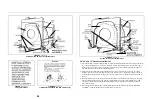

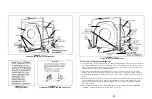

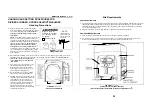

Figure 4.

A Configuration that Prevents Flow in the Machine When the Pump is Off (if the chemical

tube and tank have no pressure)

Schematic View

Legend

I.

Chemical inlet on the

machine

L.

Chemical tube

P.

Pump

T.

Chemical tank

Prevent Damage from Chemical Supplies and Chemical Systems

20

Summary of Contents for 42044SR2

Page 2: ......

Page 4: ......

Page 8: ......

Page 9: ...Installation 1 5 ...

Page 37: ...Î FIGURE 8 MSIN0301AE Î Vibration Switch Î FIGURE 9 MSIN0301AE Î 60 Staph Guard 33 ...

Page 51: ...586DA4 BUecU CicdU CSXU QdYS B5EC5 D1 9 CD1 1D9 1 4 5B1D9 C9 1 15 1F _V 47 ...

Page 53: ...Dimensional Drawings 2 49 ...

Page 54: ......

Page 55: ...51 ...

Page 56: ...52 ...

Page 57: ...53 ...

Page 58: ...54 ...

Page 59: ...55 ...

Page 60: ...56 ...

Page 61: ...57 ...

Page 62: ...58 ...

Page 63: ...59 ...

Page 64: ......

Page 65: ...61 ...

Page 66: ...62 ...

Page 67: ...63 ...

Page 68: ...64 ...