Design: Components and Function

2

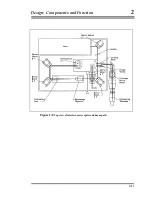

The rotation monitor (Figure 2-13) is used to monitor and record the rotation

of the test mass during each drop. The rotation monitor consists of a rigid

anodized aluminum housing mounted on the top flange of the dropping

chamber, above the viewing port. The rotation monitor employs a very

sensitive optical lever system to measure and record the rotation of the test

mass which can be used as a means to reject bad drops or determine when the

mechanical system is not functioning properly. A diode laser produces a

visible beam which is directed onto and reflects from a mirror attached to the

top of the dropped object. The reflected beam is sent through a lens and is

focused onto a two axis position sensitive photodetector. This system rejects

translation and is only sensitive to rotation. The diode laser beam reflects off

mirror #1 and the beamsplitter (mirror mount #2). The beam then passes

down through the dropping chamber viewing port, where it reflects off a flat

mirror which is mounted to the top of the test mass. The return beam from

the test mass mirror passes through the beamsplitter and reflects off mirror

#3. The beam then passes through the 200 mm focusing lens, which is

adjusted to eliminate cross coupling of translations which would otherwise

appear as rotations. The beam is then reflected off mirror #4 and enters the

detector box. The output from the quad detector is used to provide rotation

information to the computer/system controller. Each rotation monitor is

calibrated by Micro-g Solutions to determine the rotation and translation

sensitivity. These data are used to calculate rotation errors. The rotation data

can also be displayed on the computer screen, and is recorded in the DDT

output data file.

2-22

Summary of Contents for FG5

Page 22: ...Design Components and Function 2 Figure 2 10 The Superspring 2 14 ...

Page 31: ...Design Components and Function 2 Figure 2 13 Rotation Monitor 2 23 ...

Page 32: ......

Page 42: ...How to Set Up and Run the FG5 3 3 10 ...

Page 44: ...How to Set Up and Run the FG5 3 Figure 3 2 V Post 3 12 ...

Page 53: ...How to Set Up and Run the FG5 3 1 Backup the data 2 Shut off computer power 3 21 ...

Page 87: ...Adjustment and Maintenance 4 4 29 ...

Page 91: ...Adjustment and Maintenance 4 4 33 ...

Page 104: ...Troubleshooting 5 5 2 ...

Page 117: ...Troubleshooting 5 5 15 ...

Page 131: ...Checklists and Logs Appendix D 9 3 ...

Page 140: ...Checklists and Logs Appendix D Table 9 6 Replacing Drive Belt 9 12 ...

Page 145: ...Checklists and Logs Appendix D Table 9 10 Replace Linear Bearings 9 17 ...

Page 149: ...Checklists and Logs Appendix D Table 9 13 Replace Shaft Encoder 9 21 ...