11

Below are some considerations when installing the MIDAS

®

Gas Detector:

1. Mount the detector on a surface that is flat, firm and suitable for its size and weight.

2. Use the drill template supplied to drill the holes for the fixings.

3. Use fixings appropriate for the surface being mounted to.

4. Ensure the head size of fixings used will not snag the terminal PCB.

5. Consider the conduit/cable weight and its stress on the installation.

6. Position the detector so that it can be easily accessed.

7. Position the detector so that it is at a suitable height (normally eye level) for the display to be clearly seen.

8. Take into consideration the space required to remove the detector’s cover and locking/unlocking the sensor

cartridge locking clips.

9. Take into consideration the space required for sample inlet and exhaust tubing (for remote monitoring),

and for the inlet filter (for local monitoring).

10. Take into consideration the space required for cable or conduit access.

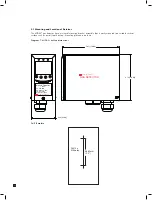

5.2 Mechanical Installation

The following steps and diagrams show how to separate the mounting bracket assembly from the main

chassis and mount it on a vertical flat surface.

1. Unscrew the thumbscrew located on the front panel.

2. Remove the cover by pulling it forwards off the main chassis.

3. Unscrew the two retaining screws located at the bottom front of the chassis.

4. Holding the mounting bracket assembly with one hand use the other to carefully pull the main chassis

forwards to disconnect it from the mounting bracket assembly.

5. Using the drill template provided drill two holes 58.50 mm vertically apart for 2 x round head M4 fixing screws.

6. Partially screw the fixings into the mounting surface.

7. Place the mounting bracket assembly over the screws so they pass through the mounting holes and then

slide down to locate in the slots.

8. Tighten the screws to secure the mounting bracket assembly.

Diagram 8. Mechanical installation