UK: Martindale Automatic Welding Helmet 9/13 User Instructions

FR: Casque de soudage automatique (Teinte 9/13)

– Mode d’emploi

ES: Instrucciones de casco para soldar automático 9/13

DE: Automatischer Schweißhelm 9/13

– Gebrauchsanleitung

024-001-783 REV A 03/17 Pag

e

7 of 39 M23AWH/13

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

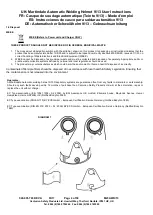

Main specifications

1.

Filter dimension

110x90x8.5 mm

2.

View area

97 x 47 mm

3.

Light shade number

4

4.

Dark shade number

5-9/9-13

5.

UV/IR protection

up to DIN15

6.

Time from light to dark

0.08ms

7.

Time from dark to light

0.1-0.9s

8.

Sensitivity /Delay

adjustable stepless solar

9.

Power supply

cells & replaceable battery

10.

Operating temperature

10°C-65°C (14°F-149°F)

11.

Grind function

Yes

12.

Optical Classification

1/2/1/1

13.

Battery

CR2450

14.

Warranty

12 months

Method of operation

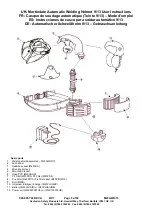

1.

Assemble the mask as shown in the construction and assembly figure (see page 9)

2.

The power supply

The power of M23AWH 9/13 helmet is provided by solar cells with one lithium battery. Turning on or off is automatic controlled

by circuit. You can use this helmet at any time you need and take it away after working without operating any key. Using this

helmet is fully free like glass filter helmet.

3.

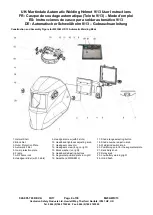

Darkness selection

Striking the arc, the observing window darkens immediately. At this moment, according to the technical requirement, the operator

adjusts the darkness knob 13 in the direction as shown by the arrow to select the optimum darkness.

Move the knob 17 leftward to choose shade from 5-9 and rightward to choose shade from 9-13.

Please refer to page 8 for shade recommendations.

4.

Delay time selection

By moving the

DELAY

selector knob 22 on the rear of the cartridge, the time taken for the lens to lighten after welding can be

altered from 0• 1-0.9 second.

Turn to

MIN:

The time the lens lighten after welding changes to be shorter. The shortest time is about 0.1 second depending

upon welding point temperature and shade set. This setting is ideal for track welding or production welding with short welds.

Turn to

MAX:

The time the lens lighten after welding changes to be longer. The longest time is about 0.9second depending

upon welding point temperature and shade set. This setting is ideal for welding at high amperage where there is an after glow

from the weld.

5.

Sensitivity selection.

By moving the

SENSITIVITY

selector knob 21 on the rear of the cartridge, the sensitivity to ambient light changes can be altered.

Turn to

LO:

The photosensitivity changes to be lower.

Suitable for high amperage welding and welding in bright light conditions (lamp light or sun light).

Turn to

HI:

The photosensitivity changes to be higher.

Suitable for low amperage welding and using in pool light conditions.

Suitable for using with steady arc process such as TIG welding.

If the helmet can be used normally, we suggest using this helmet with a bit high sensitivity.

6.

Because the shape of man's head varies from person to person. The work position and the observing angle is different, operator

may adjust the headband adjusting button 14 and the segmental positioning plate 15 to select an appropriate observing angle.

By pushing and turning the adjustment screw 10, the perimeter of the head band can be adjusted.

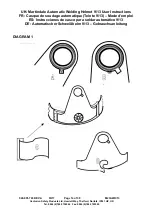

7.

Lock & Unlock

Turn to left (*-) to unlock the ADF frame. Turn to right (-

*•) to lock the ADF frame.

8.

Welding/grinding function

Welding/grinding function can be selected by moving

the adjusting knob 19.

9.

Low battery warning light

The light 23 will flash when the battery is low.

10.

Grind flash

The light 24 will flash when using grind function.

To avoid any harm to eyes, do not conduct welding while on grinding mode

Points for attention

•

Be sure that the helmet is used in correct condition and check it according to WARNING content.

•

There is liquid crystal-valve in the filter, although it has inner and outer protection plate, it is important to avoid heavy knock to