LTC3115-1

30

Rev. C

For more information

APPLICATIONS INFORMATION

PCB Layout Considerations

The LTC3115-1 buck-boost converter switches large cur-

rents at high frequencies. Special attention should be paid

to the PC board layout to ensure a stable, noise-free and

efficient application circuit. Figure 16 and Figure 17 show

a representative PCB layout for each package option to

outline some of the primary considerations. A few key

guidelines are provided below:

1. The parasitic inductance and resistance of all circulating

high current paths should be minimized. This can be

accomplished by keeping the routes to all bold compo-

nents in Figure 16 and Figure 17 as short and as wide

as possible. Capacitor ground connections should via

down to the ground plane by way of the shortest route

possible. The bypass capacitors on PV

IN

, PV

OUT

and

PV

CC

/V

CC

should be placed as close to the IC as possible

and should have the shortest possible paths to ground.

2. The exposed pad is the electrical power ground

connection for the LTC3115-1 in the DHD package.

Multiple vias should connect the backpad directly to

the ground plane. In addition, maximization of the met-

allization connected to the backpad will improve the

thermal environment and improve the power handling

capabilities of the IC in both the FE and DHD packages.

3. The components shown in bold and their connections

should all be placed over a complete ground plane to

minimize loop cross-sectional areas. This minimizes

EMI and reduces inductive drops.

4. Connections to all of the components shown in bold

should be made as wide as possible to reduce the

series resistance. This will improve efficiency and

maximize the output current capability of the buck-

boost converter.

5. To prevent large circulating currents in the ground plane

from disrupting operation of the LTC3115-1, all small-

signal grounds should return directly to GND by way

of a dedicated Kelvin route. This includes the ground

connection for the RT pin resistor, and the ground con-

nection for the feedback network as shown in Figure 16

and Figure 17.

6. Keep the routes connecting to the high impedance,

noise sensitive inputs FB and RT as short as possible

to reduce noise pick-up.

7. The BST1 and BST2 pins transition at the switching

frequency to the full input and output voltage respec-

tively. To minimize radiated noise and coupling, keep

the BST1 and BST2 routes as short as possible and

away from all sensitive circuitry and pins (VC, FB, RT).

In many applications the length of traces connecting to

the boost capacitors can be minimized by placing the

boost capacitors on the back side of the PC board and

routing to them via traces on an internal copper layer.

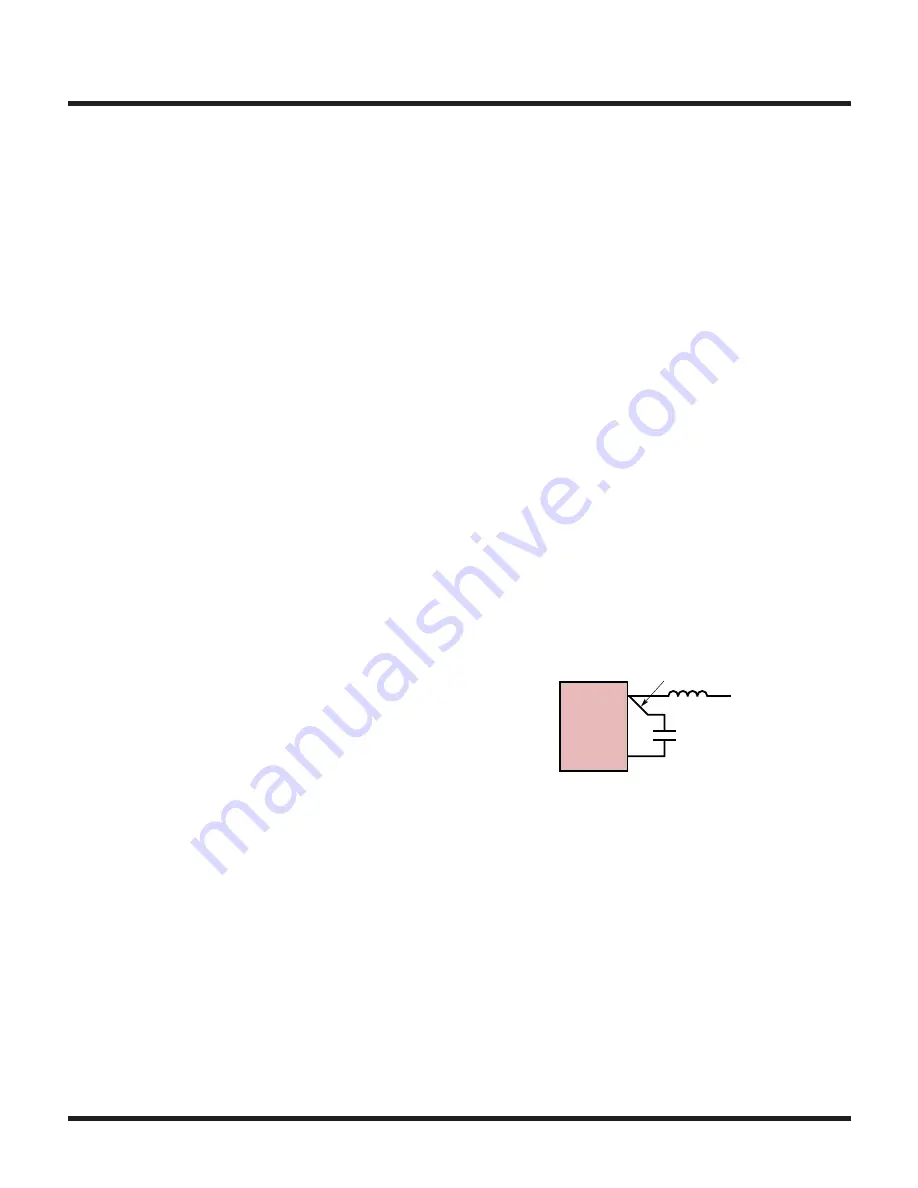

8 Connections from the BST1 and BST2 capacitors must

Kelvin directly back to the respective SW pin as shown

in Figure 15.

THIS ROUTE MUST KELVIN CONNECT

DIRECTLY BACK TO THE SW2 PIN

0.1µF

31151 F15

SW2

LTC3115-1

BST2

Figure 15. Kelvin BST Connections

9. If the optional Schottky diode from SW2 to PV

OUT

is

utilized, the Schottky should be placed as close to the

SW2 and PV

OUT

pins as possible and connected with

the shortest possible traces.