7. Commissioning

7.1 General

The product described operates automatically. However it is recom-

mended that you regularly verify that the lubricant is correctly trans-

ported along the lines.

The level of lubricant in the reservoir, if present, must be checked

visually at regular intervals. When the lubricant level is low, fill up

with lubricant, as described in chapter Filling with lubricant.

CAUTION

Always respect the equipment manufacturer's recommen-

dations concerning which lubricant to use.

CAUTION

Only use a clean lubricant. Soiled lubricants can cause

major defects in the system.

Different lubricants must not be mixed together. Doing so

can cause damage and require extensive cleaning of the

lubrication system. To prevent any risk of error, it is recom-

mended to clearly identify the lubricant used on the

reservoir.

Depending on the nature of the lubricant used, the user

should wear protective equipment such as glasses, a mask

and gloves. For further information please consult the tech-

nical file and the safety data sheet for the lubricant used.

7.2 Control Unit

The UCDE central unit features an integrated command and control

unit. The main function of this unit is to trigger a lubrication pulse

upon reception of a signal from the proximity sensor placed on the

chain to be lubricated.

Table 6

Buttons on the control unit

Button

Description

Manual start of the lubrication / stop of the lubrication in

progress

Navigation or increment

Navigation or decrement

Validation / access to a parameter for modification (press

ca. 5 s)

7.2.2 Control unit menus

The control unit software has seven main menus. These menus are

numbered for easy identification.

1

Display: real-time display of the lubrication status

2

Lubrication: configuration of lubrication mode (cyclic, semi-auto-

matic or continuous) and cycle time in case of cyclic lubrication

(modifiable by the user).

3

Number of axes: configuration of number of axes to be lubricated

on the chain for each lubrication cycle (changeable by the user)

4

Pitch jump: lubrication frequency according to lubrication points

5

Pump control: pump control setting

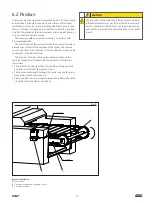

7.2.1 Interface

The command and control unit features an easy-to-use interface in

front of the UCDE unit housing

(† fig. 16)

.

This interface includes:

• a 2 × 16 digit screen

• four buttons

(† Table 6)

• a LED (default)

Fig. 16

User interface

24

Summary of Contents for SKF CLK

Page 37: ...37 ...