3 Design and function

3.1 General

CLK lubrication systems have a central unit and all electrical and

hydraulic components necessary to operate a lubrication system by

airless oil projection. The central unit comprises a housing with an

electromagnetic pump and an integrated control unit and a reservoir.

Their compact design makes it very easy to implement the CLK lubri-

cation systems as close as possible to the lubrication points located

on a moving chain.

3.2 Versions

The CLK lubrication system can be sold as a kit, mainly containing:

• the CLK central unit

• the projection nozzles

• the inductive proximity sensor

• the lubricant lines

• etc.

The table 1 gives an overview of the several existing kits

3.3 Construction

3.3.1 Central unit

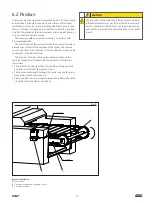

The central unit

(† fig. 1)

is a compact group comprising a reservoir

mounted on a pump housing.

The pump housing houses an electromagnetic pump and an inte-

grated control unit. The control unit can be controlled and monitored

from the control panel located on the housing front side. For more

information on the control unit, refer to the section 6.2 Control unit.

The unit electrical connections are located under the rear part of

the housing. It comprises three connectors (power supply, proximity

sensor and fault outputs). A fourth connector can be optionally added

to check the lubricant level.

The hydraulic outlets (lubricant) are located on the housing side.

The reservoir, with a usable capacity of 7.5 l, is made of

translucent plastic to facilitate the control of the lubricant level.

Four mounting plates, placed on the reservoir rear side (×2) and

on the pump housing rear side (×2) allow the easy mounting of the

central unit against a wall or the machine wall.

3.3.2 Lubrication system kits

The complete kit of the CLK lubrication system includes, in addition

to the central unit, different accessory subsets:

• long pipe

• short pipe

• nozzles

• inductive proximity sensor

Table 1

Order information, oil lubrication system

Central unit

Nozzle

1)

Proximity switch

1)

Tube

1)

Kit No.

Flow rate

Outlets

Single

Double

Ø

Temperature

Range

short

long

CLK-460R-100+XXX

2)

60

4

–

4

12

-40 to +85 °C

7 mm

1

1

CLK-260R-100+XXX

2)

60

2

–

2

12

-40 to +85 °C

7 mm

1

–

CLK-460R-110+XXX

2)

60

4

–

4

18

–20 to +180 °C

8 mm

1

1

CLK-430R-101+XXX

2)

30

4

4

–

12

-40 to +85 °C

7 mm

1

1

CLK-430R-121+XXX

2)

30

4

4

–

2

-40 to +85 °C

4 mm

1

1

*) For more information on subsets, see technical data

2) The order number has to be completed with the voltage key of the central unit:

428

for 230 V AC, 50/60 Hz and

429

for 115 V AC, 50/60 Hz

10

Summary of Contents for SKF CLK

Page 37: ...37 ...