6.2 Position

The system must be mounted in a way that protects it from humidity

and vibrations. It should also be easily accessible so that all other

installation work can be carried out without hindrance. Ensure that

there is sufficient circulating air to prevent the system from overhea-

ting. For information on the maximum admissible ambient tempera-

ture, see the technical data section.

The product should be mounted vertically in accordance with

documentation data.

The control panel of the control unit should be easily accessible to

allow the user to control the operation of the system and to make

various adjustments. The lubricant reservoir should be clearly visible

to easily check the lubricant level.

The location of the lubricating system always depends on the

machine configuration. However, SKF recommends to follow this

instructions:

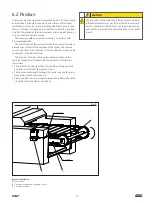

• The projection nozzles should be placed at the starting point and

above the return belt of the conveyor chain

• The line maximum length between the central unit and the projec-

tion nozzles should not exceed 5 m.

• The connection maximum length between the central unit and the

proximity sensor should not exceed 5 m.

CAUTION

The projection nozzles and the proximity sensor operate in

different temperature ranges. It is not therefore necessary

to check the ambient temperature and the working tempe-

rature of the place where the nozzles and the sensor will be

placed.

2,5 m max

5 m max

1

2

3

Fig. 5

System installation

1

Central unit

2

Projection nozzles and proximity sensor

3

Projection nozzles

17

Summary of Contents for SKF CLK

Page 37: ...37 ...