PIPEFAB™ WELDING SYSTEM

OPERATION

B-30

Example 2: 2-Step Trigger: Improved Arc Start and Arc End.

Tailoring the arc start and arc end is a common method for reducing spa

�e

r and improving weld quality.

This can be accomplished with the Start and Burnback func

�

ons set to a desired values and Crater set to

OFF.

For this sequence,

PREFLOW:

Shielding gas begins to

fl

ow immediately when the gun trigger is pulled.

RUN-IN:

A

�e

r pre

fl

ow

�

me expires, the power source regulates to the start output and wire is

advanced towards the work piece at the Run-In WFS. If an arc is not established within

2.0 seconds, the power source output and wire feed speed skips to the weld se

�

ngs.

START:

Once the wire touches the work and an arc is established, both the machine output and

the wire feed speed ramp to the weld se

�

ngs throughout the start

�

me. The

�

me

period of ramping from the start se

�

ngs to the weld se

�

ngs is called UPSLOPE.

WELD:

A

�e

r upslope, the power source output and the wire feed speed con

�

nue at the weld

se

�

ngs.

BURNBACK:

As soon as the trigger is released, the wire feed speed is turned OFF and the machine

output con

�

nues for the burnback

�

me.

POSTFLOW:

Next, the machine output is turned OFF and shielding gas con

�

nues un

�l

the post

fl

ow

�

mer expires.

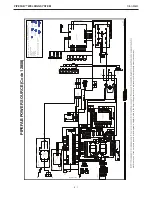

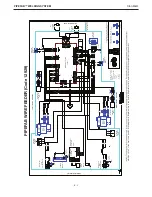

FIGURE B.25

Summary of Contents for PIPEFAB CE

Page 18: ...PIPEFAB WELDING SYSTEM INSTALLATION A 3 FIGURE A 1 ...

Page 97: ......