PIP

E

FAB™ WELDING SYSTEM

INSTALLATION

A-8

WIRE DRIVE PRESSURE SETTING

Most wires operate well with a pressure se

�

ng of “2”. The best drive roll pressure varies with wire

type, wire surface, lubrica

�

on and hardness. Too much pressure may crush the wire or cause

"birdnes

�

ng", but too li

�

le pressure could cause slippage.

Se

�

ng the drive roll pressure

1. Press the end of the gun against a solid object that is electrically isolated from the welder output and

press the gun trigger for several seconds.

2. If the wire "birdnests" or jams, the drive roll pressure is too high. Reduce the pressure by one turn of

the knob, run new wire through the gun, and repeat step 1.

3. If the only result is slippage, disconnect the gun and pull the gun cable forward about 6" (150mm).

There should be a slight waviness in the exposed wire. If there is no waviness, increase the pressure

se

�

ng one turn, reconnect the gun and repeat the above steps.

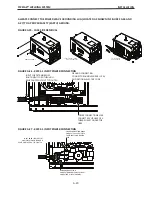

FIGURE A.8

Summary of Contents for PIPEFAB CE

Page 18: ...PIPEFAB WELDING SYSTEM INSTALLATION A 3 FIGURE A 1 ...

Page 97: ......