112

Rooftop Dedicated Outdoor

Air System Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Dampers

Inspect the dampers periodically. Check that all linkages are operating smoothly and that the damper blade seals are in good condition.

Clean the damper rod bushings.

Interior and Exterior

Clean the inside of the unit regularly with a disinfectant to prevent the buildup of dirt and the growth of microorganisms that can negatively

affect the indoor air quality. Clean all metal surfaces including walls, racks, partitions, floors, and heat transfer surfaces.

Clean the exterior casing occasionally to prevent buildup of foreign material that can cause corrosion. The required frequency of cleaning

depends on the location of the unit. If the paint is damaged, remove any corrosion and repaint the surface.

Check the condition of gaskets around doors.

Blower

When the unit is operating, a routine maintenance schedule should be carried out and include:

• Tighten the fan’s wheel, bolts, and set screws.

• Clean dirt from the wheel to prevent imbalance and possible damage.

• Tighten motor mounting bolts and blower/motor assembly support bolts.

• Check rubber isolators (if applicable) for deterioration.

MAINTENANCE

Blower Motor Lubrication

The ball bearings in the blower motor have been lubricated at the

factory. Motors that cannot be re-greased are factory lubricated for

the normal life of the bearings.

For motors that can be re-greased, lubrication is recommended at

the following intervals. New motors that have been stored for a year

or more should also be re-lubricated.

For information about bearing lubrication, refer to the motor manu-

facturer’s documentation. Blower motors are pre-greased.

Motors can be re-greased while stopped (at less than 176°F) or

running.

1. Clean the grease fitting.

2. If the motor has a purge plug, remove it.

3. Slowly apply grease to the fitting. Refer to the following table for

the recommended amount of grease to add. Too much grease or

injecting grease too quickly can cause premature bearing failure.

Take a minute or more to apply the grease.

4. Operate the motor for twenty (20) minutes, then reinstall the

purge plug if it was previously removed.

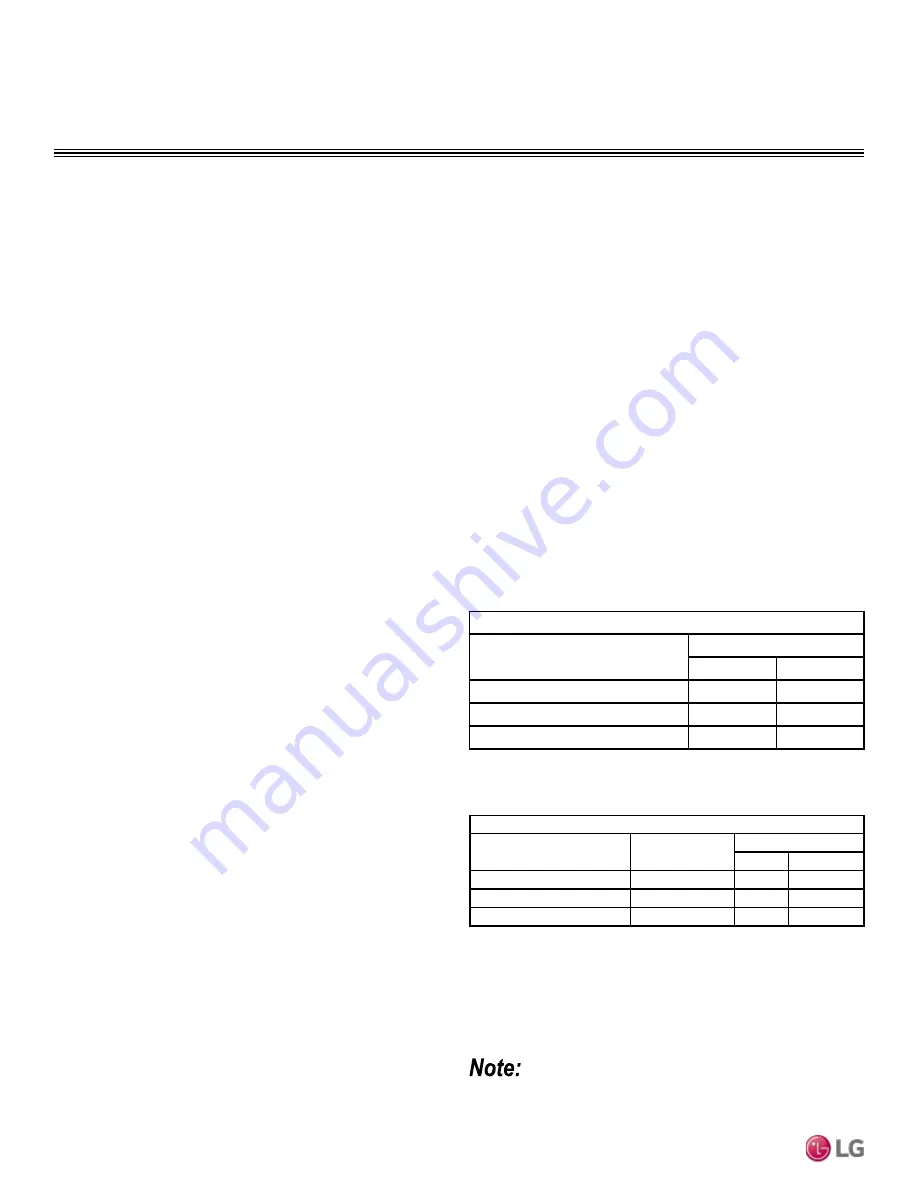

Lubrication Intervals

Frame Size NEMA (IEC)

Rated Speed (RPM)

1,200

1,800

56 (80)

5,000 hours

N/A

Up to 210 incl. (132)

18,000 hours 12,000 hours

Over 210 to 280 incl. (180)

15,000 hours 9,500 hours

Table 71:

Blower Motor Lubrication.

Keep grease clean. Mixing dissimilar greases is not recommended and

may cause product malfunction.

Table 72:

Blower Motor Grease.

Amount of Grease to Add

Frame Size NEMA (IEC)

By Weight

ounces (grams)

By Volume

Inches Teaspoons

56 (80)

0.14 (4.0)

0.25

0.8

Up to 210 incl. (132)

0.30 (8.4)

0.6

2

Over 210 to 280 incl. (180)

0.61 (17.4)

1.2

3.9