Leuze electronic GmbH + Co. KG

In der Braike 1 D-73277 Owen

We reserve the right to make changes

[email protected] • www.leuze.com

Tel. +49 (0) 7021 573-0

03/2020 - 50134631-02 - 5/20

Notes

•

The two-hand control device and the upstream and

downstream parts of the controller must conform to the

applicable VDE regulations and the safety requirements set

out in ISO 13851:2019, EN 692, and EN 693.

•

The performance level (PL) and safety category in

accordance with EN ISO 13849-1 depend on the external

wiring, the application case, the choice of control device

and how this is physically arranged on the machine.

•

The user must carry out a risk assessment in accordance

with ISO 14121-1.

•

The entire system/machine must undergo validation in

accordance with the applicable standards on the basis of

this.

•

The stated performance level will only be achieved if,

taking into account the prevailing device load (see

EN ISO 13849-1 Table C.1) and the application case, an

average number of switching cycles per year is not

exceeded (see EN ISO 13849-1, C.4.2 and Table K.1).

With an electrical service life of 1,000,000 switching cycles,

at 1 A (resistive load and 230 V AC), the maximum number

of cycles, for example, can be calculated as 1,000,000 /

0.1 x 39 = 256,410 switching cycles/year.

•

Correct functioning and monitoring of synchronous

operation must be checked at least once a year.

•

Only the enabling current path 11-14 may be used to

enabled hazardous movement. The current signalling path

11-12 is only permitted for non-safety-related tasks.

•

Operating the device other than specified can result in

malfunctions or destruction of the device.

•

The device must be installed so that there is no risk of

short circuits, in particular between T11 and T13.

•

The device must be checked to ensure it is in perfect

working order before commissioning, after replacement of

modules and/or in the case of changes to an installation

that has already undergone acceptance.

•

The expansion units of the MSI-SR-CM series or external

contactors with positively-driven contacts can be used for

duplicating the enabling current paths.

•

The contacts must be fused with maximum 4 A operating

class gG.

•

External loads must be equipped with a suitable

protection circuit for the load (e.g. RC elements, varistors,

suppressors, etc.) in order to reduce electromagnetic

interference and increase the service life of the output

switching elements.

•

The application-specific standards must be observed

when installing and operating the device.

•

The switch-on peak current must be considered when

connecting solenoid switches with reed contacts or

sensors with semiconductor outputs (see Technical data).

•

The safety functions have not been checked by UL. The

certification process has been carried out in accordance

with the requirements for general applications as

stipulated by UL508.

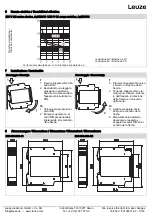

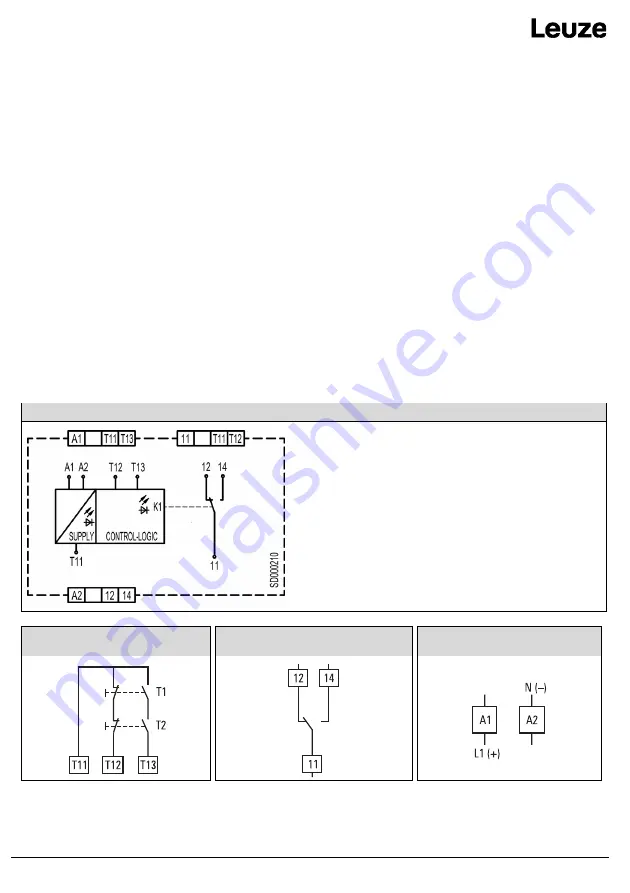

3

Connection diagrams

MSI-SR-2H1 AC/DC 24 V

1 Two-hand pushbuttons T1 and T2

2 - 1 changeover contact (enabling cur-

rent path and current signalling path)

3 - Power supply