Installation and Operational Instructions for ROBA

®

-twinstop

®

Type 8012._ _ _ _ _ Sizes 150 to 350

(B.8012.GB)

05/07/2010 TK/HW/SU

Chr. Mayr GmbH + Co. KG

Tel.: 08341 / 804-0

Eichenstraße 1

Fax: 08341 / 804-421

D-87665 Mauerstetten

http://www.mayr.de

Page 13 of 15

Germany eMail:

Electrical Connection for Operation

with Nominal Voltage (Without Overexcitation)

DC current is necessary for operation of the brake. The coil

voltage is indicated on the Type tag (14) as well as on the brake

body and is designed according to the DIN IEC 60038 (± 10 %

tolerance). Operation must take place via DC voltage with a low

ripple content, e.g. via a bridge rectifier or with another suitable

DC supply. Dependent on the brake equipment, the connection

possibilities can vary. Please follow the exact connections

according to the Wiring Diagram. The manufacturer and the user

must observe the applicable directives and standards (e.g. DIN

EN 60204-1 and DIN VDE 0580). Their observance must be

guaranteed and double-checked!

Earthing Connection

The brake is designed for Protection Class I. This protection

covers not only the basic insulation, but also the connection of

all conductive parts to the PE conductor on the fixed installation.

If the basic insulation fails, no contact voltage will remain.

Please carry out a standardized inspection of the PE conductor

connections to all contactable metal parts!

Supply Voltage Requirements

In order to minimise noise development of the released brake, it

must only be operated via DC current with low ripple content. AC

current operation can take place using a bridge rectifier or

another suitable DC power supply. Supplies whose output

voltages have a high ripple content (e.g. a half-wave rectifier, a

switch-mode mains adaptor, ...) are not suitable for operation of

the brake.

Device Fuses

To protect against damage from short circuits, please add

suitable device fuses to the mains cable.

Switching Behaviour

The operational behaviour of a brake is to a large extent

dependent on the switching mode used. Furthermore, the

switching times are influenced by the temperature and the air

gap between the armature disk (2) and the coil carrier (1)

(dependent on the wear condition of the linings).

Magnetic Field Build-up

When the voltage is switched on, a magnetic field is built up in

the brake coil, which attracts the armature disk (2) to the coil

carrier (1) and releases the brake.

Magnetic Field Removal

AC-side Switching

The power circuit is interrupted

before the rectifier. The

magnetic field slowly reduces.

This delays the rise in braking

torque.

When switching times are not

important, please switch AC-

side, as no protective

measures are necessary for

coil and switching contacts.

Low-noise switching;

however, the brake engagement time

is longer (c. 6-10 times longer than with DC-side switching). Use

for non-critical brake times.

DC-side Switching

The power circuit is interrupted

between the rectifier and the

coil as well as mains-side. The

magnetic field reduces

extremely quickly. This causes

a quick rise in braking torque.

When switching DC-side, high

voltage peaks are produced in

the coil, which lead to wear on

the contacts from sparks and

to destruction of the insulation.

Short brake engagement times (e.g. for emergency

STOP);

however, louder switching noises.

Protective Circuit

When using DC-side switching, the coil must be protected by a

suitable protective circuit according to VDE 0580, which is

integrated in

mayr

®

rectifiers. To protect the switching contact

from consumption when using DC-side switching, additional

protective measures are necessary (e.g. series connection of

switching contacts). The switching contacts used should have a

minimum contact opening of 3 mm and should be suitable for

inductive load switching. Please make sure on selection that the

rated voltage and the rated operation current are sufficient.

Depending on the application, the switching contact can also be

protected by other protective circuits (e.g.

mayr

®

-spark

quenching unit), although this may of course then alter the

switching time.

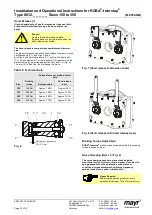

1

2

3

4

5

6

230V~

max.

2,5A–

1/025.000.6

Brückengleichrichter

Bridge rectifier

IN

S

DC

OUT

[U– = 0,9×U~]

S1

F1

L

N

F1: external fuse

Coil

1

2

3

4

5

6

230V~

max.

2,5A–

1/025.000.6

Brückengleichrichter

Bridge rectifier

IN

S

DC

OUT

[U– = 0,9×U~]

S1

F1

L

N

F1: external fuse

Coil

Summary of Contents for E27 Series

Page 4: ...4 E27 Gearless Installation and maintenance 5323 en 2018 04 c...

Page 15: ......

Page 46: ...30 31 NOTES...

Page 109: ......

Page 110: ......

Page 111: ......