Technical specifications

INTORQ | BA 14.0197 | 06/2014

12

3

Technical specifications

3.1

Product description

Versions

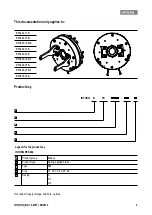

Fig. 1

Design of the BFK464-

S / S.1 / S.2 spring-applied brake

3.1.1

General information

The spring-applied brake is designed for converting mechanical work and kinetic energy into heat energy.

Due to the static braking torque, loads can be held at standstill. Emergency braking is possible at high speed

of rotation. The wear increases as the switching energy increases (operating speeds

17).

The BFK464 spring-applied brake is a single-disk brake with two friction surfaces. The braking torque is ap-

plied through two separate braking circuits, both electrical and mechanical, via several compression springs

(1.2) in the form of generated friction. The brake circuits are released electromagnetically. Due to its division

into two brake circuits, the brake is particularly suitable for applications such as lift systems and stage/plat-

form technology. The brake can be selected based on the rated torque for one brake circuit. The second

brake circuit meets the requirement for redundancy.

1.1 Stator

5

Shaft

10 Socket head cap screw, DIN EN ISO

4762

1.2 Pressure springs

6

Flange (optional)

13 Cover plate (optional)

2

Armature plate

8

Coil

16 Microswitch

3

Complete rotor

9

Sleeve bolts

18 Silencer (optional)

4

Hub

2

1.2

3

4

6

1.1

8

9

16

13

5

18

10

2

Summary of Contents for E27 Series

Page 4: ...4 E27 Gearless Installation and maintenance 5323 en 2018 04 c...

Page 15: ......

Page 46: ...30 31 NOTES...

Page 109: ......

Page 110: ......

Page 111: ......