Installation and Operational Instructions for ROBA

®

-twinstop

®

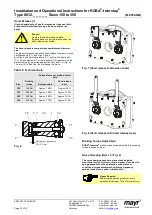

Type 8012._ _ _ _ _ Sizes 150 to 350

(B.8012.GB)

05/07/2010 TK/HW/SU

Chr. Mayr GmbH + Co. KG

Tel.: 08341 / 804-0

Eichenstraße 1

Fax: 08341 / 804-421

D-87665 Mauerstetten

http://www.mayr.de

Page 3 of 15

Germany eMail:

Safety Regulations

These Safety Regulations are user hints only and may not be complete!

Insulation Material Class F (+155 °C)

The magnetic coil and the casting compound are suitable for

use up to a maximum operating temperature of +155 °C.

Brake Storage

Store the brakes in a horizontal position, in dry rooms and

dust and vibration-free.

Relative air humidity < 60 %.

Temperature without major fluctuations within a range from

– 20 ° up to +60° C.

Do not store in direct sunlight or UV light.

Do not store aggressive, corrosive substances (solvents /

acids / lyes / salts etc.) near to the brakes.

For longer storage of more than 2 years, special measures are

required (please contact the manufacturers).

Handling

Before installation, the brake must be inspected and found to be

in proper condition. The brake function must be inspected both

once installation has taken place as well as after longer system

downtimes, in order to prevent the drive starting up against

possibly seized linings.

User-implemented Protective Measures:

Please cover moving parts to protect against injury through

seizure.

Place a cover on the magnetic part to protect against injury

through high temperatures.

Protect against electric shocks by installing a conductive

connection between the magnetic component and the PE

conductor on the permanent installation (Protection Class I)

and by carrying out a standardised inspection of the

continuous PE conductor connection to all contactable

metal parts.

Protect against highly inductive switch-off peaks by

installing varistors, spark quenching units or similar devices

according to VDE 0580/2000-07, Paragraph 4.6, to prevent

damage to the coil insulations or switch contact

consumption in extreme conditions (this protection is

contained in

mayr

®

rectifiers).

Take precautions against freeze-up of the friction surfaces

in high humidity and at low temperatures.

Regulations, Standards and Directives Used:

DIN VDE 0580 Electromagnetic devices and components,

general directives

2006/95/EC

Low voltage directive

2004/108/EC

EMC directive

95/16/EC

Elevator directive

EN 81-1

Safety regulations for

construction and installation of elevators and

small goods elevators

BGV C1

(previously VGB 70) Safety regulations for

theatre stage technical systems

Please Observe the Following Standards:

DIN EN ISO

12100-1 and 2

Machine Safety

DIN EN 61000-6-4 Noise emission

EN12016

Interference resistance

(for elevators, escalators and moving

walkways)

EN 60204

Electrical machine equipment

Liability

The information, guidelines and technical data in these

documents were up to date at the time of printing.

Demands on previously delivered brakes are not valid.

Liability for damage and operational malfunctions will not

be taken if

- the Installation and Operational Instructions are ignored or

neglected.

- the brakes are used inappropriately.

- the brakes are modified.

- the brakes are worked on unprofessionally.

- the brakes are handled or operated incorrectly.

Guarantee

The guarantee conditions correspond with the

Chr. Mayr GmbH + Co. KG delivery conditions.

Mistakes or deficiencies are to be reported to

mayr

®

at

once!

Conformity Markings

The product confirms to the CE according to the low voltage

directive 2006/95/EC.

Identification

mayr

®

components are clearly marked and described on the

Type tag:

Manufacturer

mayr

®

Name/Type

Article number

Serial number

Summary of Contents for E27 Series

Page 4: ...4 E27 Gearless Installation and maintenance 5323 en 2018 04 c...

Page 15: ......

Page 46: ...30 31 NOTES...

Page 109: ......

Page 110: ......

Page 111: ......