20 / 31

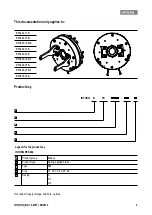

Fig. 24

In brakes that have optical detectors (

micro-switches

) mounted, on connecting/disconnecting the

brake the red LED of the detector must change status.

Fig. 25

Should any of the

micro-switches

not behave in the way described above it may be necessary to

readjust or replace the detector. Consult point 7.2 “

Replacement and adjustment of detectors

(micro-switches)”.

Check that the detector is clean.

Check that the rubber dust-cover fits and prevents the insertion of particles or light (in the case of

optical

micro-switches

) in the detector.

Exposing of the microswitches to silicon gas may cause their dysfunction.

6.3 Winding verification:

Checking the resistance: Check that the resistance of the winding is correct. A reading below that

shown on the characteristics plate will be a sign that the winding has been damaged. In this case

it will be necessary to replace the brake as a whole. Consult the nominal value of the resistance

in section 1.5

“General characteristics”

.

7 SPARE PARTS:

Spare parts are considered to be those components that may be replaced in the installation of

the lift without prejudice to the safety of the brake.

7.1 Disc replacement:

21 / 31

Danger: the following process leads to releasing the brake, with the consequent

risk of uncontrolled movement of the lift cabin and the counterweight.

Danger of entrapment.

Carrying out this process may require prior withdrawal of the encoder and

subsequent assembly and readjustment.

1. Once the installation has been secured, remove the plastic caps and position and tighten the

shipping screws, painted red, to avoid the brake dismantling.

Fig. 26

Fig. 27

Summary of Contents for E27 Series

Page 4: ...4 E27 Gearless Installation and maintenance 5323 en 2018 04 c...

Page 15: ......

Page 46: ...30 31 NOTES...

Page 109: ......

Page 110: ......

Page 111: ......