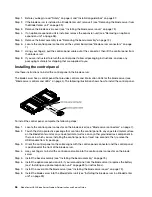

d. Press firmly on the heat sink.

e. Align the screws on the heat sink with the holes on the heat-sink retention module.

f.

Press firmly on the captive screws and tighten them with a screwdriver, alternating among the

screws until they are tight. If possible, each screw should be rotated two full rotations at a time.

Repeat until the screws are tight. Do not overtighten the screws by using excessive force. If

you are using a torque wrench, tighten the screws to 8.5 Newton-meters (Nm) to 13 Nm (6.3

foot-pounds to 9.6 foot-pounds).

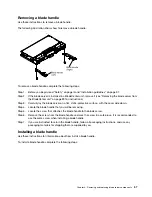

Step 8. Install the optional expansion unit, if you removed one from the blade server to replace the battery

(see “Installing an optional expansion unit” on page 59 for instructions).

Step 9. Install the cover onto the blade server (see “Installing the blade server cover” on page 73).

Step 10. Install the blade server into the BladeCenter unit (see “Installing the blade server in a BladeCenter

Thermal grease

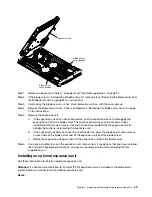

Use this information to determine the guidelines for using thermal grease on a heat sink and processor.

The thermal grease must be replaced whenever the heat sink has been removed from the top of the

microprocessor and is going to be reused or when debris is found in the grease.

To replace damaged or contaminated thermal grease on the microprocessor and heat sink, complete the

following steps:

Step 1. Place the heat-sink assembly on a clean work surface.

Step 2. Remove the cleaning pad from its package and unfold it completely.

Step 3. Use the cleaning pad to wipe the thermal grease from the bottom of the heat sink.

Note:

Make sure that all of the thermal grease is removed.

Step 4. Use a clean area of the cleaning pad to wipe the thermal grease from the microprocessor; then,

dispose of the cleaning pad after all of the thermal grease is removed.

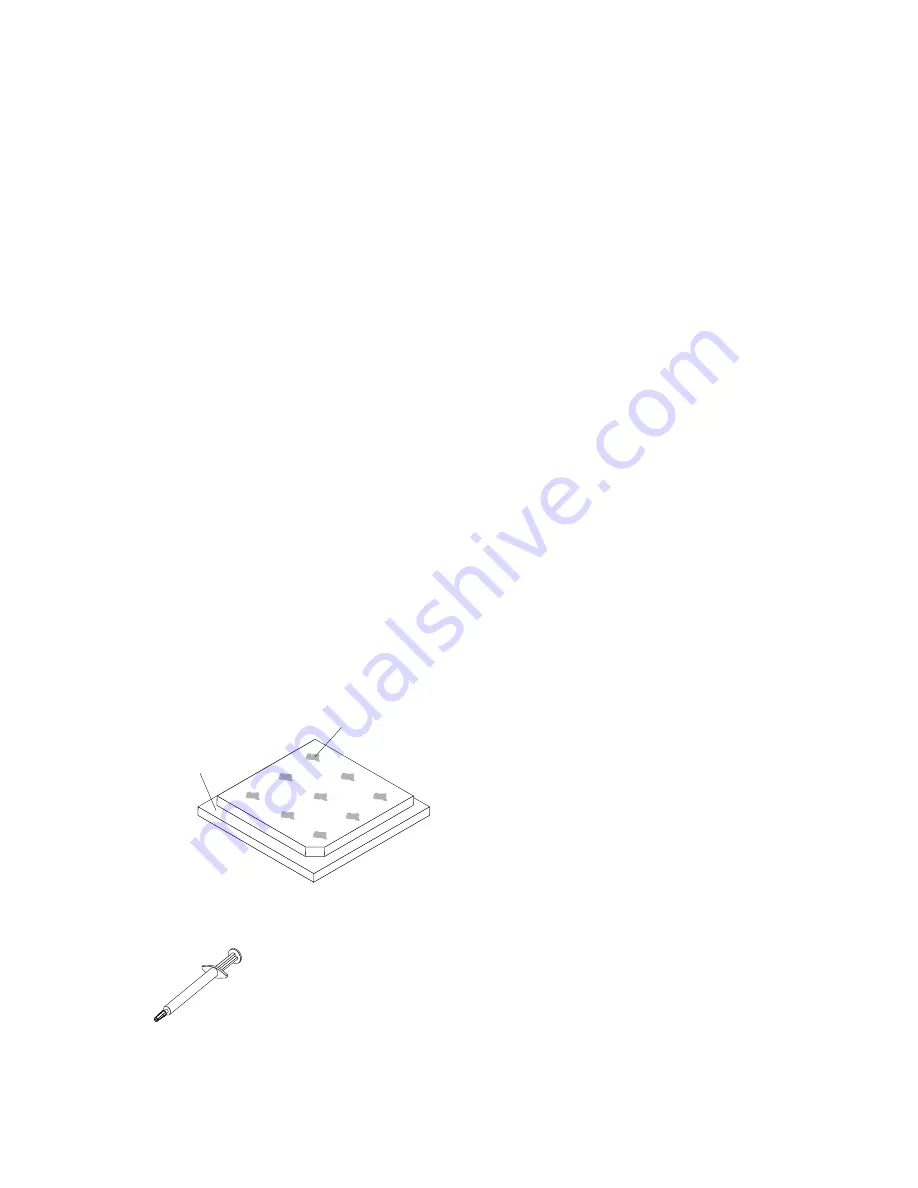

Microprocessor

0.02 mL of thermal

grease

Step 5. Use the thermal-grease syringe to place nine uniformly spaced dots of 0.02 mL each on the top of

the microprocessor.

Note:

0.01mL is one tick mark on the syringe. If the grease is properly applied, approximately half

(0.22 mL) of the grease will remain in the syringe.

70

BladeCenter HS23 Blade ServerProblem Determination and Service Guide

Summary of Contents for BladeCenter HS23 1929

Page 1: ...BladeCenter HS23 Blade Server Problem Determination and Service Guide Machine Types 7875 1929 ...

Page 284: ...268 BladeCenter HS23 Blade ServerProblem Determination and Service Guide ...

Page 289: ...Taiwan BSMI RoHS declaration Appendix B Notices 273 ...

Page 290: ...274 BladeCenter HS23 Blade ServerProblem Determination and Service Guide ...

Page 296: ...280 BladeCenter HS23 Blade ServerProblem Determination and Service Guide ...

Page 297: ......

Page 298: ...Part Number 00KC215 Printed in China 1P P N 00KC215 ...

Page 299: ... 1P00KC215 ...