49

21) DUAL LEAF DOOR

Two automations are required to control the operation of a dual leaf swing door, one which must be setup as Master and the other that

must be setup as Slave.

In the case of overlapping leaves, setup as Master the automation applied to the first leaf which opens.

In case of swing door with two leaves overlapping when closed and installed on emergency exits, the person in charge of

commissioning shall measure the force necessary to open both leaves of the door pushing manually the Slave leaf in the

direction of the escape (most unfavourable condition).

The force necessary to open manually the door must not exceed 150N and must be measured at the main edge, at a right

angle with respect to the leaf, at an height of 1000 ± 10mm.

If the force measured is higher than the limit of 150N, apply the symbol for emergency breakout only on the main leaf

(Master) of the door.

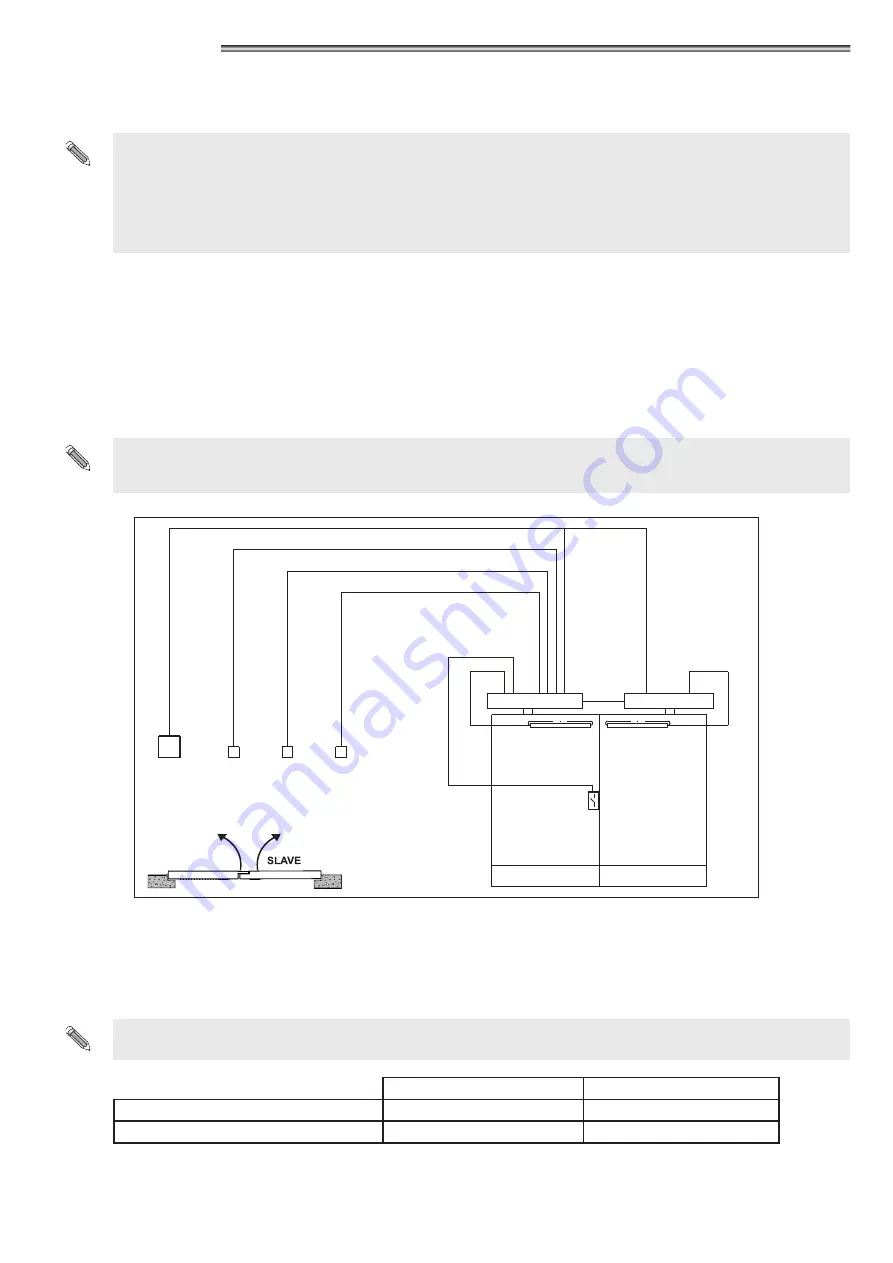

21.1) DUAL LEAF ELECTRIC SETUP

Make the electrical connections to the automations (see paragraph "Electrical connections"), considering that the door opening control

actuators, the program selector, and the electric lock must be connected to the Master automation.

The safety sensors installed on the master leaf must be connected to the Master automation, the safety sensors installed on the slave

leaf must be connected to the Slave automation.

If the door is equipped with dual electric lock to lock individually each leaf, connect to the Slave automation the electric lock which locks

the Slave leaf.

The Master and Slave automations must be connected via the wiring "WR5MS", whose terminals must be inserted into the

connector J7 of the logic boards NEXT-L120S of the automations.

Connect to the Master automation the digital selector EV-DSEL or T-NFC.

LINEA

ALIMENTAZIONE

DI RETE

SELETTORE

DI

PROGRAMMA

RADAR

DI

APERTURA

COMANDO

OPEN

NEXT 75 MASTER

CABLAGGIO

WR5MS

NEXT 75 SLAVE

SENSORI DI

SICUREZZA

ELETTROSERRATURA

ANTA 1 (MASTER)

ANTA 2 (SLAVE)

SENSORI DI

SICUREZZA

MASTER

21.2) DUAL LEAF DOOR COMMISSIONING

After having completed the mechanical installation and performed the electric connections, check manually that the motion of both leaves

is without friction for the entire run.

Before powering the system set the SW1 dip-switch of the NEXT-L120S logic board as specified in the table

SW1 DIP 1

SW1 DIP 2

NEXT-L120S MASTER AUTOMATION

OFF

OFF

NEXT-L120S SLAVE AUTOMATION

OFF

ON

NEXT 120S MASTER

NEXT 120S SLAVE