4

GENERAL SAFETY WARNINGS

Carefully read this instruction manual for the safe installation and operation of the automatic door.

Improper installation and incorrect use of the product could cause serious injury.

Keep the instruction manual for future reference.

The installer must provide all the information about operation and provide the system user with the user manual delivered with the

product.

MEANING OF THE SYMBOLS USED IN THESE INSTRUCTIONS

DANGER

:

Notification of dangerous situations that could cause material damage and personal injury.

WARNING:

Identifies the procedures that must be understood and followed mandatorily in order to avoid damage to the product or

malfunctions.

NOTE

:

Highlights important information.

GENERAL SAFETY OBLIGATIONS

The mechanical and electric installation must be performed by specialised personnel in accordance with the applicable

directives and regulations.

The installer must make sure that the structure to be automated is stable and robust and, if necessary, make structural

modifications to make it so.

Keep product and packaging materials out of children's reach, as they might be a source of danger.

Do not let children stay or play within the operating range of the door.

This product is designed and built exclusively for the purpose described in this documentation. Any other use that is not specifically

indicated could adversely impact the condition of the product and the safety of people.

Label accepts no responsibility for incorrect product installation and usage, as well as for any damage caused by changes made without

its prior consent.

Label is not responsible for the construction of the frames to be motorised.

The IP32 protection class requires that the automation is installed only on the inner side of buildings.

This product cannot be installed in explosive environments or atmospheres, or in the presence of flammable gases or fumes.

Make sure that the characteristics of the electric distribution network are compatible with the technical data indicated in this manual and

that upstream of the system there is an omnipolar switch with an opening distance of the contacts of at least 3mm and a residual current

device.

The automatic door must be checked, started up, and tested by personnel skilled and trained about the product.

A technical dossier must be compiled for every automation, as established in the Machinery Directive.

Disconnect the power supply before working on the automation and before opening the cover.

Maintenance is of fundamental importance for the proper operation and safety of the automation. Check the efficiency of all parts every

six months.

Use only original spare parts for maintenance and when replacing product components.

Cleaning operations must be performed with the power supply disconnected, using a damp cloth. Do not deposit or let water or other

liquids penetrate into the automation or the accessories that are part of the system.

It is recommended to subscribe a maintenance contract.

The automatic swing doors must be designed and installed so as to protect users against the risk and danger of crushing,

impact, and shearing between the leaf and adjacent parts near the door outline.

The person responsible for starting-up the automation must perform a risk assessment based on the place of installation

and the type of users that could use the automatic door.

The automation NEXT 120S, as provided for by the standard EN16005, must be equipped with the safety devices (sensors)

compliant with the standard EN12978.

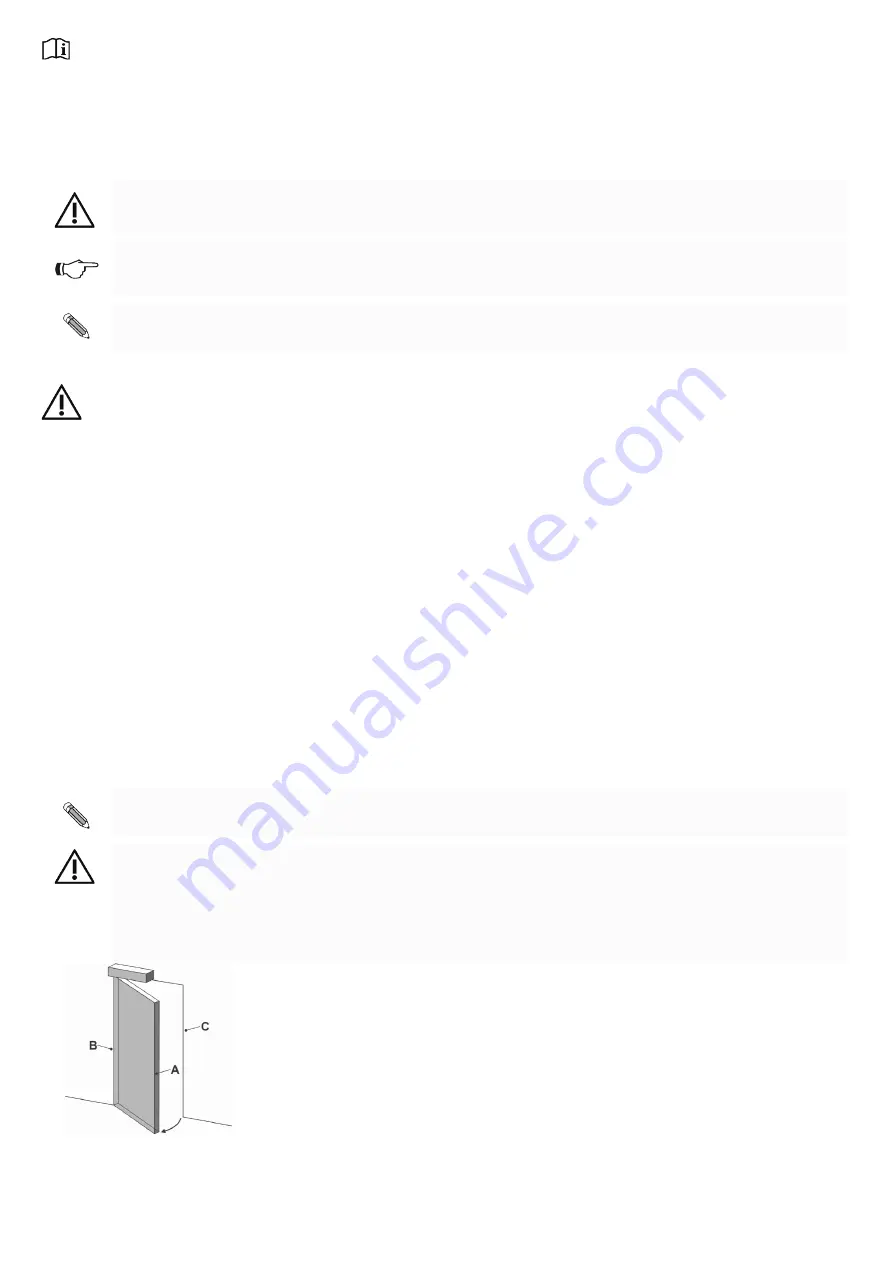

A = Main closing edge

B = Secondary closing edge

C = Opposite closing edge

The crushing and shearing dangers on the secondary closing edge must be protected structurally or

by means of additional safety provisions (e.g., rubber covers).

Any residual risks must be properly highlighted.