52

21.3) FUNCTIONAL TESTING

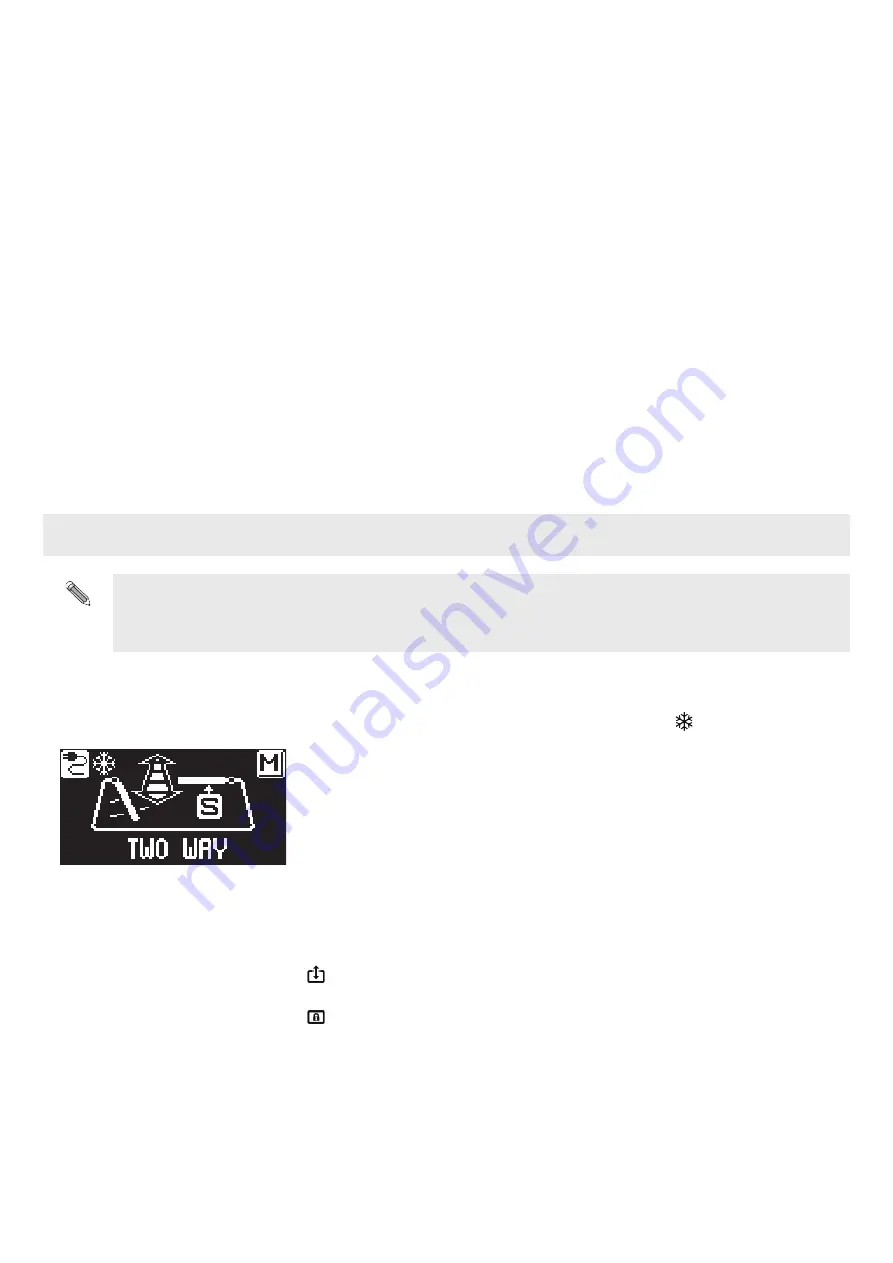

Select the automatic operation of the door using the program selector.

If you use the program manual selector, set it to l.

Refer to the “Program selectors” paragraph describing the types of selector provided for to select the automatic door operating mode.

To start an opening movement, press briefly the button PS1 (Start) on the control unit NEXT-L120S of the Master automation, or operate

the door opening devices.

Check the correct execution of the door opening and closing cycle

During the opening cycle, the Slave leaf starts with a preset delay with respect to the Master leaf, while in the closing cycle the Master

leaf starts with a preset delay with respect to the Slave leaf.

The delay between the leaves at start is fundamental to avoid a possible crossing during the run, risking to overlap; if you want to change

the preset leaf delay, enter the section “Functions and adjustments” and use the potentiometer P30 to adjust the delay of the leaf during

opening and the potentiometer P31 to adjust the leaf delay during closing (see paragraph 14.2 “Potentiometers adjustment”).

Ensure that thrust organs and safety sensors operate; to adjust sensor detection field, refer to the instructions provided with the sensor.

The detection of the safety sensor during opening stops the motion only of the leaf on which it is installed.

The detection of the safety sensor during closing reverses the opening motion on both leaves.

Safety on impact: check that when there is an obstacle to the motion of a leaf, both leaves stop and reverse their motion.

After having powered the system, the first opening cycle occurs at slow speed and you can choose with the function F35 if both leaves

must start together, or one after the other, respecting the leaf delay.

F35 OFF = In the first opening cycle the leaves start together.

F35 ON = In the first opening cycle the leaves start one after the other, respecting the leaf delay.

To set up the available functions, refer to “Functions setup” paragraph.

To adjust the variable parameters, refer to the paragraph “Potentiometers adjustment”.

Setup operation must be repeated if one of the following conditions changes:

weight of the door, leaf opening angle, replacement of the logic board NEXT-L120S, arm removal (see paragraph 5.5).

In this case, select the PARTIAL option from “setup mode” to perform only the leaf run learning without changing the

current settings.

21.4) PARTIAL OPENING

From the automatic door work program, it is possible to select the partial opening option, used to open only the Master leaf.

•

If the automation is equipped with the digital selector ET-DSEL or T-NFC (F01 = ON), press the button

to enable partial opening.

•

If the automation is equipped with the manual selector or the mechanical key selector EV‑MSEL (F01 = OFF), to enable partial

opening it is necessary to set the function

F36m

.

Then you should select in which position of the selector the partial opening must be enabled:

F36 = B:

partial opening in position 0 in the manual program selector;

partial opening in position

in the mechanical selector EV‑MSEL.

F36 = D:

partial opening in position II in the manual program selector;

partial opening in position

in the mechanical selector EV‑MSEL.

PARTIAL OPENING OPERATION

The opening commands, given via the internal and external radar inputs and with push & go, actuate the partial opening of the door,

therefore only the Master leaf.

The opening commands given via the OPEN input lead to the full opening of both leaves.