2-46

CHAPTER 2 OUTLINE OF OPERATION

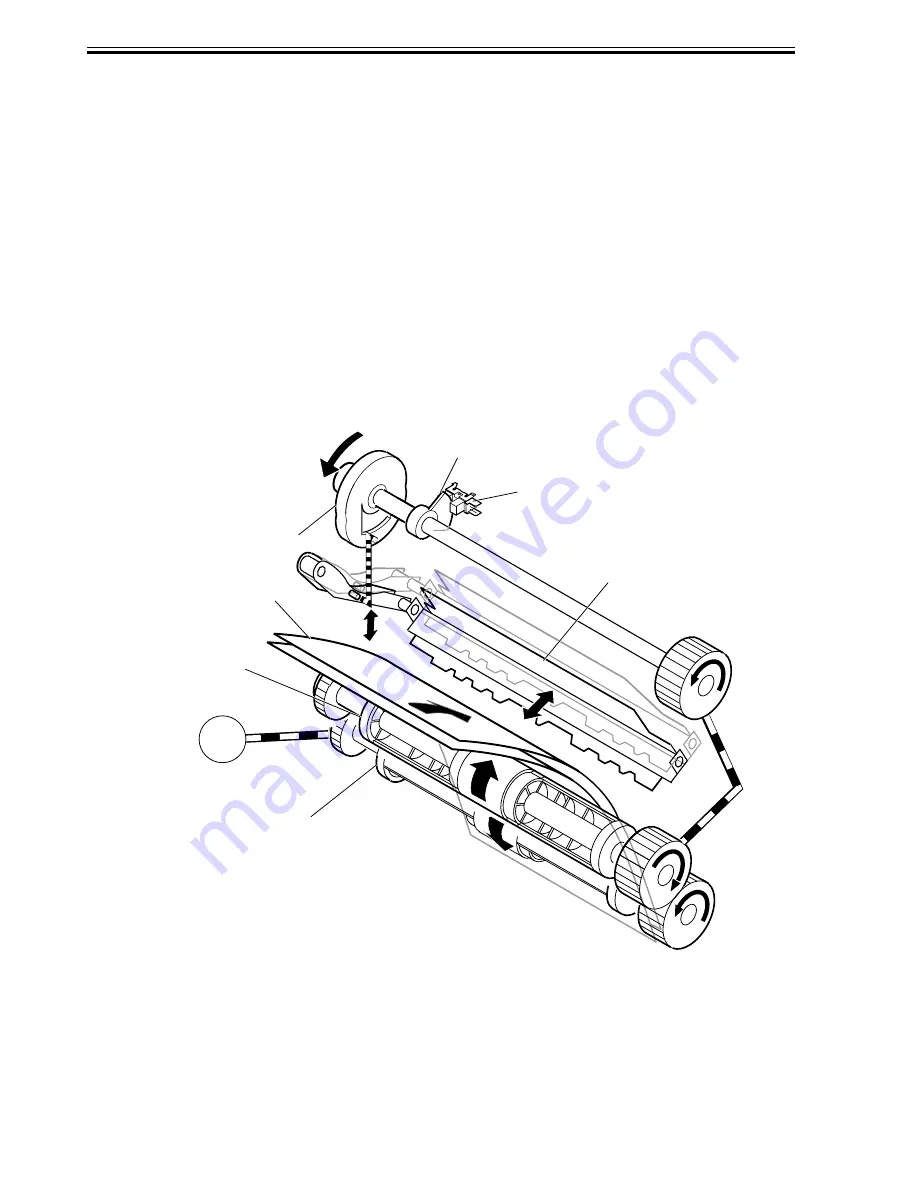

5.5.2 Paper Folding

Paper is folded using paper fold rollers and a paper pushing plate.

Almost concurrently with the start of roller rotation, the paper pushing plate starts operating

to push the paper stack into the gap between the paper fold rollers. When the paper stack is

fed about 10 mm with the rotation of the paper fold rollers, the paper pushing plate returns to

the home position. Then, the paper stack is delivered to the bind tray using the paper fold roll-

ers and bind delivery rollers.

Half the entire surface of each paper fold roller is uncovered excluding the central area and

the area at the left and right ends. The uncovered surface of the upper paper fold roller comes

in touch with the uncovered surface of the lower paper fold roller only at the center and left

and right ends, allowing a paper stack to be fed without causing creases. The other half of the

upper paper fold roller that is covered comes in touch with the other half of the lower paper

fold roller that is also covered, allowing a paper stack to be folded while being fed.

F02-505-01

M7

Paper fold roller (lower)

Paper fold roller (upper)

Paper pushing plate

Folding home position sensor (PI11)

Sensor flag

Came

Paper stack

Staple/fold

motor

Summary of Contents for DF-75

Page 1: ...SERVICE MANUAL Published in Aug 01 5FG70760 DF 75...

Page 12: ...CHAPTER 1 GENERAL DESCRIPTION...

Page 24: ...CHAPTER 2 OUTLINE OF OPERATION...

Page 89: ...CHAPTER 3 MECHANICAL SYSTEMS...

Page 132: ...CHAPTER 4 MAINTENANCE AND INSPECTION...

Page 135: ...CHAPTER 5 TROUBLESHOOTING...

Page 142: ...5 7 CHAPTER 5 TROUBLESHOOTING...

Page 145: ...5 10 CHAPTER 5 TROUBLESHOOTING 2 1 2 Motor PCBs M7 M8 M5 M4 M3 M6 M1 M2 1 F05 201 02...

Page 175: ...5 40 CHAPTER 5 TROUBLESHOOTING...

Page 176: ...APPENDIX...

Page 180: ...A 4...

Page 184: ...A 8 APPENDIX...

Page 198: ...A 22...