OPERATION

OPERATION

3-127

INSPECTION AND ADJUSTING

3

q

Adjust the track shoe to the proper tension.

When adjusting the tension, measure clearance A between

the idler and carrier roller in the diagram on the right. The

normal clearance is 20 to 30 mm, but on bedrock, set the

tension slightly higher, and on viscous ground, set it slightly

looser.

(Inspect and adjust the track tension. For details of the

method of inspection and maintenance for the track ten-

sion, see “WHEN REQUIRED (4-21)“.

q

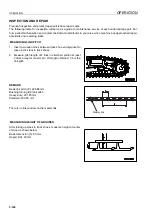

Check idler rollers for oil leakage as well as for loose bolts

and nuts. If any trouble is detected, repair immediately.

q

Check clearance B between the idler guide plate and track

frame. If clearance B becomes larger, the idler will move to

the side and cause the track shoe to come off. For details

of the method of inspection and maintenance, see

“ADJUST IDLER CLEARANCE (4-36)“.

Clearance A

Guide plate

Clearance B

Summary of Contents for 76243

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 5: ...FOREWORD FOREWORD 1 3 q Machine equipped without cab Back pocket of operator s seat ...

Page 16: ...NECESSARY INFORMATION FOREWORD 1 14 ...

Page 17: ...FOREWORD NECESSARY INFORMATION 1 15 ...

Page 24: ...CONTENTS 1 22 ...

Page 28: ...SAFETY LABELS SAFETY 2 4 SAFETY LABELS 2 POSITIONS OF SAFETY PICTOGRAMS 2 ...

Page 289: ...SPECIFICATIONS 15 ...

Page 297: ...INDEX 17 ...

Page 298: ...INDEX 7 2 ...

Page 301: ...COLOPHON 18 ...