OPERATION

OPERATION

3-112

OPERATING ON SLOPES

3

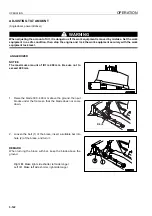

When using the variable ripper, adjust the length of the tilt cylin-

der to select dimension L.

Slope face: Sloping face, such as on embankments

METHOD OF OPERATING PIN PULLER

3

This operation is used only when a giant ripper is installed.

1.

Stop the machine at a safe place and lower the shank com-

pletely to the ground.

2.

Operate the pin-puller control switch to remove the mount-

ing pin.

3.

Raise or lower the ripper to set the shank to the desired

position.

4.

Operate the pin-puller control switch to insert the mounting

pin. If the pin and hole in the shank are not aligned, set the

pin puller control switch to “Push in“ and move the ripper

up or down slowly.

q

When inserting the pin in a higher hole in the shank in

order to carry out deep ripping operations, use a long

protector to prevent wear of the shank.

REMARK

If the mounting pin cannot be removed by operating the switch,

move the ripper slightly up or down and tilt it. This will make it

possible to remove the pin.

Top surface

Mark

Align with

top surface

of holder

Depth Max.

Intermediate

Min.

Pull out

Push in

Summary of Contents for 76243

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 5: ...FOREWORD FOREWORD 1 3 q Machine equipped without cab Back pocket of operator s seat ...

Page 16: ...NECESSARY INFORMATION FOREWORD 1 14 ...

Page 17: ...FOREWORD NECESSARY INFORMATION 1 15 ...

Page 24: ...CONTENTS 1 22 ...

Page 28: ...SAFETY LABELS SAFETY 2 4 SAFETY LABELS 2 POSITIONS OF SAFETY PICTOGRAMS 2 ...

Page 289: ...SPECIFICATIONS 15 ...

Page 297: ...INDEX 17 ...

Page 298: ...INDEX 7 2 ...

Page 301: ...COLOPHON 18 ...