24

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

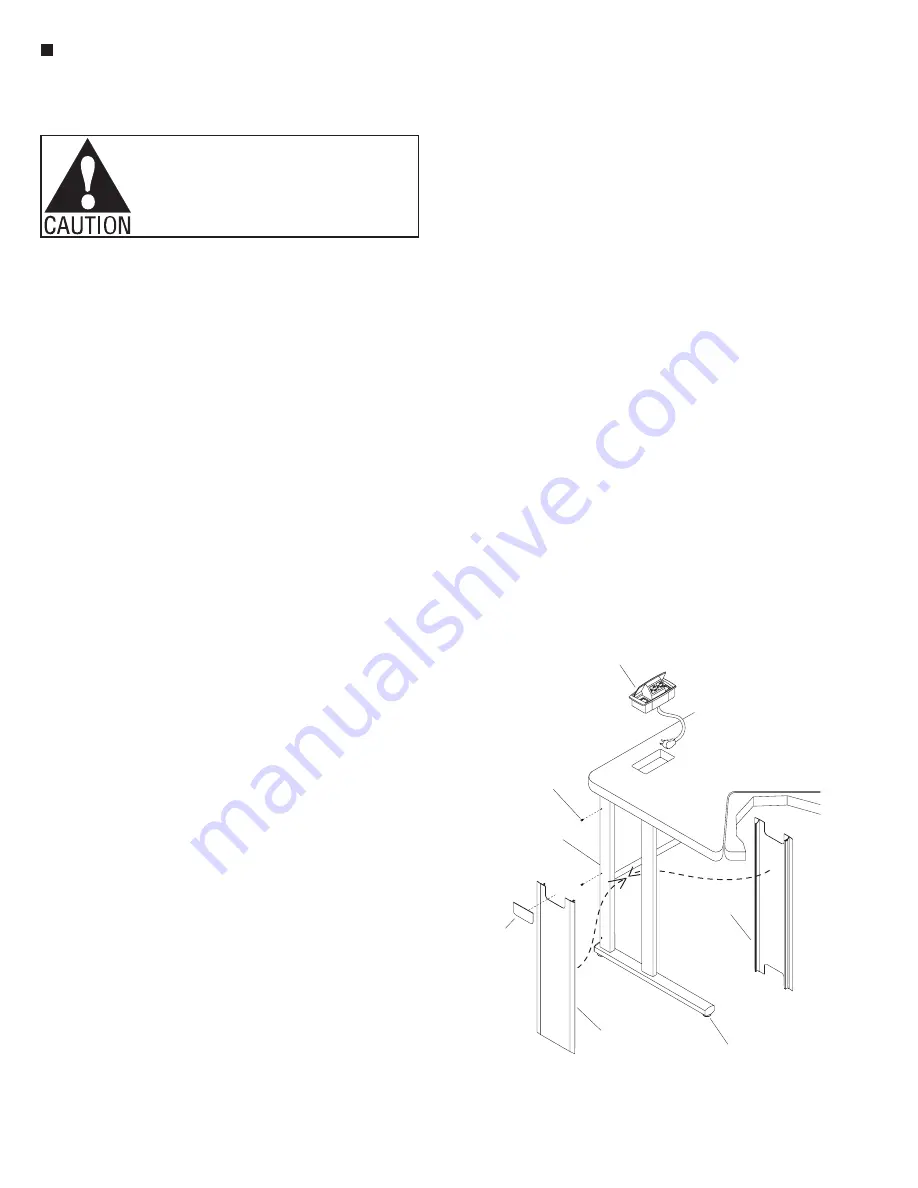

11. Secure two splice plates to

the pre-drilled holes at the

underside of the adjoining

rectangular worksurfaces.

Use two #12 x 1” screws each

(Figure 2).

12. Carefully turn the corner

worksurface right side up and

set the appropriate edge onto

the splice plates of the adjoining

rectangular worksurface. Use

four #12 x 1” screws to attach

the splice plates to the corner

worksurface. Do not tighten the

screws at this time (Figure 2).

13. Unclip and open the transitional

side power/data door under

the corner worksurface and

the power/data door under

the adjoining rectangular

work surface. Secure the

modesty panel to the leg set

of the adjoining rectangular

worksurface with two

#10 x ½” screws. Route the

trailing end of the power-pass-

through connector through the

notched vertical wireway in the

leg of the adjoining rectangular

worksurface and snap the

connector end into the 10-wire

harness (Figure 2).

Note:

All table connection must

be securely fastened before any

electrical connections between

worksurfaces are installed.

14. Route the power and data

module cord through the power

and data module hole in the

worksurface. Snap the module

into the module hole (Figure 4).

15. From under the worksurface,

with the power/data door

opened, plug the power cord

into the duplex receptacle on the

10-wire harness. Check for proper

operation of the power and data

module. To open, push down on

the module and it will pop up. To

close, press downward and it will

snap closed.

16. Level the worksurfaces by turning

the adjustable glides either in or

out. The jambnuts between the

adjustable glides and the bottom

of the leg sets must be tightened

up against the bottom of the leg

to secure the adjustable glides.

Tighten all screws that gang the

worksurfaces together at this time

(Figure 4).

17. Vertical wireways fasten into each

other from each side of the leg

set opening and must be oriented

correctly to snap together. Begin

by first positioning an “outer

vertical wireway” (single-cut-out),

to the outside of the leg set as

illustrated, with cut-out closest

to worksurface. Next position

the inner wireway cover (two

cut-outs) in the correct orientation

at the inside of the leg set and

snap it into the outer wireway

(Figure 4). For end-of run tables,

snap a vertical wireway cap into

the upper, outside cut-out in the

vertical wireway, and install leg

plugs into holes in the vertical

leg members to finish table off

(Figure 4)

18. Install a worksurface grommet

into the wireway hole at the back

corner of the worksurface

(Figure 2).

19. The power/data door that is

attached to each modesty panel

snaps into the door clips at the

underside of the worksurface.

The S-shaped power/data

divider that was installed into

the power/data door is in place

to separate power from data

lines (optional). Snap the door

to the door clips when power

and data lines have been run.

Note:

This channel is not to

be used for routing extension

cords. Power supply cords

are not to be routed across or

through more than one complete

unit/worksurface.

WorkZone

®

- Corner Transitional and End-of-Run Corner Worksurface with Power & Data

Assembly Instructions

17.

18. Install a worksurface grommet

into the wireway hole at the back

corner of the worksurface

(Figure 2).

19. The power/data door that is

attached to each modesty panel

snaps into the door clips at the

underside of the worksurface. The S-

shaped power/data divider that was

installed into the power/data door is in

place to separate power from data

lines (optional). Snap the door to the

door clips when power and data lines

have been run.

This channel is not to be used

for routing extension cords. Power

supply cords are not to be routed

across or through more than one

complete unit/worksurface.

Vertical wireways fasten into each

other from each side of the leg set

opening and must be oriented

correctly to snap together. Begin by

first positioning an “outer vertical

wireway” (single-cut-out), to the

outside of the leg set as illustrated,

with cut-out closest to worksurface.

Next position the inner wireway cover

(two cut-outs) in the correct

orientation at the inside of the leg set

and snap it into the outer wireway

(Figure 4). For end-of run tables, snap

a vertical wireway cap into the upper,

outside cut-out in the vertical

wireway, and install leg plugs into

holes in the vertical leg members to

finish table off (Figure 4)

Note:

11. Secure two splice plates to the pre-

drilled holes at the underside of the

adjoining rectangular worksurfaces. Use

two #12 x 1” screws each (Figure 2).

12. Carefully turn the corner

worksurface right side up and set the

appropriate edge onto the splice plates

of the adjoining rectangular

worksurface. Use four #12 x 1” screws

to attach the splice plates to the corner

worksurface. Do not tighten the screws

at this time (Figure 2).

13. Unclip and open the transitional side

power/data door under the corner

worksurface and the power/data door

under the adjoining rectangular work

surface. Secure the modesty panel to

the leg set of the adjoining rectangular

worksurface with two #10 x ½”screws.

Route the trailing end of the power-pass-

through connector through the notched

vertical wireway in the leg of the

adjoining rectangular worksurface and

snap the connector end into the 10-wire

harness (Figure 2).

All table connection must be

securely fastened before any electrical

connections between worksurfaces are

installed.

16. Level the worksurfaces by turning

the adjustable glides either in or out. The

jambnuts between the adjustable glides

and the bottom of the leg sets must be

tightened up against the bottom of the

leg to secure the adjustable glides.

Tighten all screws that gang the

worksurfaces together at this time

(Figure 4).

Note:

14. Route the power and data module

cord through the power and data module

hole in the worksurface. Snap the

module into the module hole (Figure 4).

15. From under the worksurface, with

the power/data door opened, plug the

power cord into the duplex receptacle on

the 10-wire harness. Check for proper

operation of the power and data module.

To open, push down on the module and

it will pop up. To close, press downward

and it will snap closed.

WorkZone with Power & Data - Assembly

Figure 4

vertical

wireway-outer

(end-of-run)

vertical

wireway-inner

leg plug

leg set

adjustable

glide

power & data

module

vertical

wireway cap

Figure 4