Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

23

Note:

If you are not assembling

an end-of-run corner

worksurface, go on to step 5.

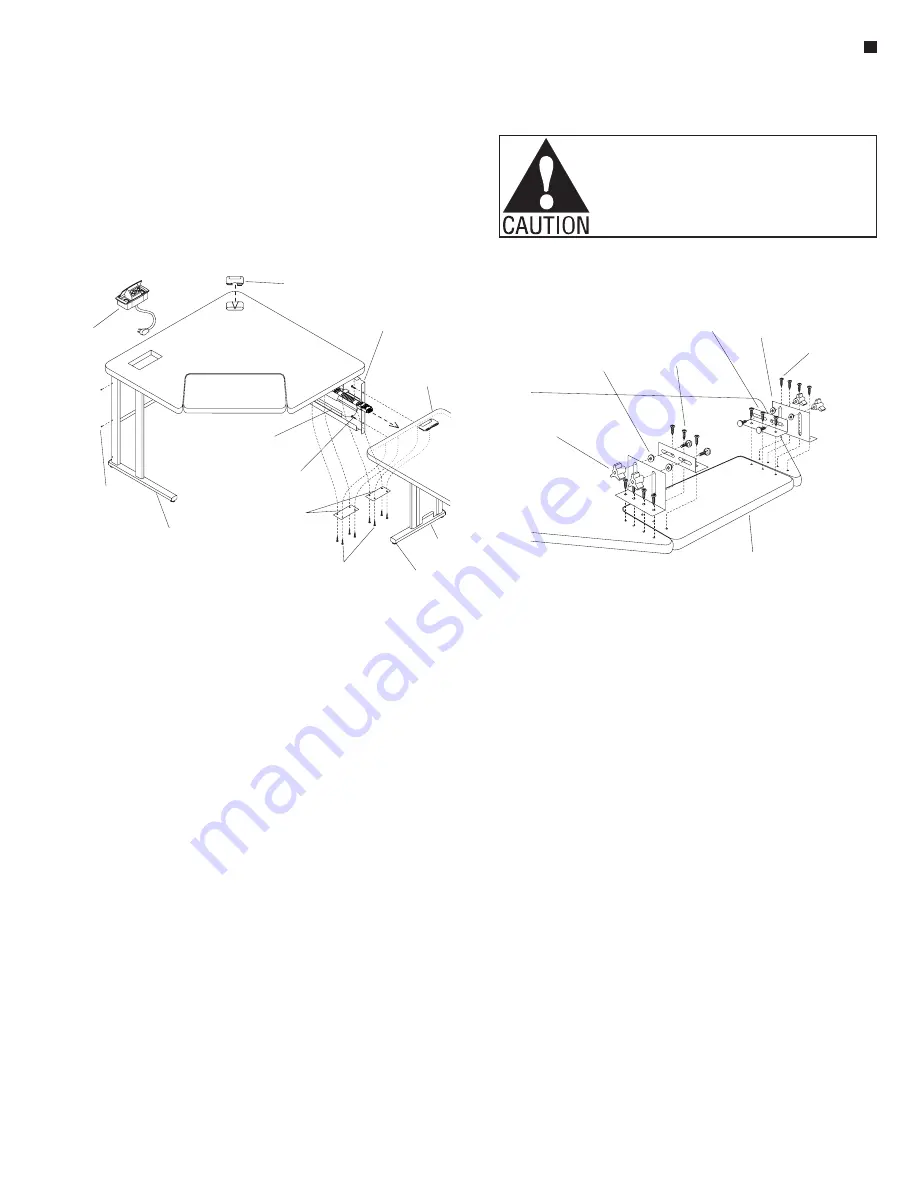

4. On the “end-of-run” side of the

corner worksurface, align a leg

set to the pre-drilled holes and

secure the leg set with three

#12 x 1

3

/

4

” screws (Figure 1).

5. Position the corner leg over the

four pre-drilled holes at the back

corner of the worksurface. Be

sure the modesty panel mounting

holes of the corner leg are

oriented as shown. Secure the

corner leg to the worksurface with

four #12 x 1” screws (Figure 1).

Note:

Corner transitional

modesty panels are the longer

of the two types of modesty

panels. They bridge between

the corner worksurface and the

adjoining rectangular worksurface

to connect the two together.

End-of-run modesty panels are

shorter and fit between the corner

leg and the “end-of-run” leg set.

6. Align the longer transitional

modesty panel with the corner

leg and the corner worksurface

mounting holes. Position the

“end-of-run” modesty panel over

the worksurface mounting holes,

between the corner leg and the

“end-of-run” leg set. Note that

the lower right screw hole in the

corner leg is to be used to secure

the power/data corner bracket and

should not be used until step 7.

Fasten the modesty panels to

the corner leg. For “end-of-run”

assemblies, attach modesty panel

to leg set with #10 x ½” screws.

Do not tighten screws at this

time.

7. Position the power/data corner

bracket into the back corner

of the worksurface against the

corner leg. Insert the #10 x ½”

screw (left out in step 6) through

the corner bracket, the modesty

panel and into the corner leg.

Do not tighten at this time. Align

the four mounting holes of the

corner bracket with the holes in

the worksurface and secure with

#12 x 1” screws (Figure 1).

8. Fasten door clips to the

underside of the worksurface

with two #12 x 1” screws per

door clip (Figure 1).

Note:

Power/data doors for

corner worksurfaces are sized

longer or shorter to correspond

with corner transitional or “end-

of-run” modesty panels. The

corner transitional power/data

door is the longer of the two.

9. Position the mounting bracket

of the appropriate power/data

door over the modesty panel

holes that correspond with the

holes in the worksurface. Insert

two #12 x 1” screws through the

mounting bracket, the modesty

panel and into the worksurface.

Tighten all screws that secure

the modesty panels to the

corner leg, the leg sets and the

worksurface (Figure 1).

10. Route the power-pass-through

connector through the power

and data corner bracket and

snap the connector into the

10-wire harness. Route the

trailing end inside the power/

data door. Snap both power/

data doors shut at the door clips

(Figure 1).

Note:

If the corner worksurface

being assembled includes

WorkZone

®

- Corner Transitional and End-of-Run Corner Worksurface with Power & Data

Assembly Instructions

a keyboard pad, follow

instructions A through D below.

Otherwise skip to step 11.

Keyboard Pad Assembly

A. Attach the two small brackets

to the keyboard pad by aligning

the holes in the small brackets

with the pre-drilled holes in the

keyboard pad. Insert three

#12 x 1” screws per bracket, but

do not tighten completely

(Figure 3).

B. Align the two large brackets to

the pre-drilled holes in the corner

worksurface. Insert four #12 x 1”

screws per large bracket, but do

not tighten (Figure 3).

C. Assemble four adjustment knobs

to connect small brackets to large

brackets. Insert carriage bolts

through small bracket, a washer,

the large bracket and secure with

an adjustment knob (Figure 3).

D. Center the keyboard pad

inside the opening in the

corner worksurface. Starting

with the large brackets on the

worksurface, tighten all bracket

screws completely (Figure 3).

Note:

Note:

If you are not assembling an end-

of-run corner worksurface, go on to step

5.

4. On the “end-of-run” side of the corner

worksurface, align a leg set to the pre-

drilled holes and secure the leg set with

three #12 x 1 / ” screws (Figure 1).

5. Position the corner leg over the four

pre-drilled holes at the back corner of the

worksurface. Be sure the modesty panel

mounting holes of the corner leg are

oriented as shown. Secure the corner leg

to the worksurface with four #12 x 1”

screws (Figure 1).

Corner transitional modesty panels

are the longer of the two types of

modesty panels. They bridge between the

corner worksurface and the adjoining

rectangular worksurface to connect the

two together. End-of-run modesty panels

are shorter and fit between the corner leg

and the “end-of-run” leg set.

6. Align the transitional modesty panel

with the corner leg and the corner

worksurface mounting holes. Position the

“end-of-run” modesty panel over the

worksurface mounting holes, between

the corner leg and the “end-of-run” leg

set. Note that the lower right screw hole

in the corner leg is to be used to secure

the power/data corner bracket and should

not be used until step 8. Fasten the

modesty panels to the corner leg. For

“end-of-run” assemblies, attach modesty

panel to leg set with #10 x ½” screws.

Do not tighten screws at this time.

3

4

7. Position the power/data corner bracket

into the back corner of the worksurface

against the corner leg. Insert the #10 x

½” screw (left out in step 6) through the

corner bracket, the modesty panel and

into the corner leg. Do not tighten at this

time. Align the four mounting holes of the

corner bracket with the holes in the

worksurface and secure with #12 x 1”

screws (Figure 1).

8. Fasten door clips to the underside of

the worksurface with two #12 x 1”

screws per door clip (Figure 1).

Note:

Note:

Power/data doors for corner

worksurfaces are sized longer or shorter

to correspond with corner transitional or

“end-of-run” modesty panels. The

corner transitional power/data door is

the longer of the two.

9. Position the mounting bracket of the

appropriate power/data door over the

modesty panel holes that correspond

with the holes in the worksurface. Insert

two #12 x 1” screws through the

mounting bracket, the modesty panel

and into the worksurface. Tighten all

screws that secure the modesty panels

to the corner leg, the leg sets and the

worksurface (Figure 1).

10. Route the power-pass-through

connector through the power and data

corner bracket and snap the connector

into the 10-wire harness. Route the

trailing end inside the power/data door.

Snap both power/data doors shut at the

door clips (Figure 1).

If the corner worksurface being

assembled includes a keyboard pad,

follow instructions A through D below.

Otherwise skip to step 11.

Keyboard Pad Assembly

A. Attach the two small brackets to the

keyboard pad by aligning the holes in the

small brackets with the pre-drilled holes

in the keyboard pad. Insert three #12 x

1” screws per bracket, but do not tighten

completely (Figure 3).

B. Align the two large brackets to the

pre-drilled holes in the corner

worksurface. Insert four #12 x 1”

screws per large bracket, but do not

tighten (Figure 3).

C. Assemble four adjustment knobs to

connect small brackets to large

brackets. Insert carriage bolts through

small bracket, a washer, the large

bracket and secure with an adjustment

knob (Figure 3).

D. Center the keyboard pad inside the

opening in the corner worksurface.

Starting with the large brackets on the

worksurface, tighten all bracket screws

completely (Figure 3).

Figure 2

Figure 3

splice

plates

corner

worksurface

worksurface

grommet

modesty panel

(transitional)

adjoining

rectangular

worksurface

#12 x 1"

screws

#12 x 1"

screw

large

bracket

small

bracket

#10 x / "

screw

1

2

#10 x / "

screw

1

2

washer

adjustment

knob

corner

worksurface

power/data

door

leg set

(end-of-run)

transitional

leg

adjustable

glide

leg plug

WorkZone with Power & Data - Assembly Instructions

power & data

module

power & data

module

Figure 2

Note:

Note:

If you are not assembling an end-

of-run corner worksurface, go on to step

5.

4. On the “end-of-run” side of the corner

worksurface, align a leg set to the pre-

drilled holes and secure the leg set with

three #12 x 1 / ” screws (Figure 1).

5. Position the corner leg over the four

pre-drilled holes at the back corner of the

worksurface. Be sure the modesty panel

mounting holes of the corner leg are

oriented as shown. Secure the corner leg

to the worksurface with four #12 x 1”

screws (Figure 1).

Corner transitional modesty panels

are the longer of the two types of

modesty panels. They bridge between the

corner worksurface and the adjoining

rectangular worksurface to connect the

two together. End-of-run modesty panels

are shorter and fit between the corner leg

and the “end-of-run” leg set.

6. Align the transitional modesty panel

with the corner leg and the corner

worksurface mounting holes. Position the

“end-of-run” modesty panel over the

worksurface mounting holes, between

the corner leg and the “end-of-run” leg

set. Note that the lower right screw hole

in the corner leg is to be used to secure

the power/data corner bracket and should

not be used until step 8. Fasten the

modesty panels to the corner leg. For

“end-of-run” assemblies, attach modesty

panel to leg set with #10 x ½” screws.

Do not tighten screws at this time.

3

4

7. Position the power/data corner bracket

into the back corner of the worksurface

against the corner leg. Insert the #10 x

½” screw (left out in step 6) through the

corner bracket, the modesty panel and

into the corner leg. Do not tighten at this

time. Align the four mounting holes of the

corner bracket with the holes in the

worksurface and secure with #12 x 1”

screws (Figure 1).

8. Fasten door clips to the underside of

the worksurface with two #12 x 1”

screws per door clip (Figure 1).

Note:

Note:

Power/data doors for corner

worksurfaces are sized longer or shorter

to correspond with corner transitional or

“end-of-run” modesty panels. The

corner transitional power/data door is

the longer of the two.

9. Position the mounting bracket of the

appropriate power/data door over the

modesty panel holes that correspond

with the holes in the worksurface. Insert

two #12 x 1” screws through the

mounting bracket, the modesty panel

and into the worksurface. Tighten all

screws that secure the modesty panels

to the corner leg, the leg sets and the

worksurface (Figure 1).

10. Route the power-pass-through

connector through the power and data

corner bracket and snap the connector

into the 10-wire harness. Route the

trailing end inside the power/data door.

Snap both power/data doors shut at the

door clips (Figure 1).

If the corner worksurface being

assembled includes a keyboard pad,

follow instructions A through D below.

Otherwise skip to step 11.

Keyboard Pad Assembly

A. Attach the two small brackets to the

keyboard pad by aligning the holes in the

small brackets with the pre-drilled holes

in the keyboard pad. Insert three #12 x

1” screws per bracket, but do not tighten

completely (Figure 3).

B. Align the two large brackets to the

pre-drilled holes in the corner

worksurface. Insert four #12 x 1”

screws per large bracket, but do not

tighten (Figure 3).

C. Assemble four adjustment knobs to

connect small brackets to large

brackets. Insert carriage bolts through

small bracket, a washer, the large

bracket and secure with an adjustment

knob (Figure 3).

D. Center the keyboard pad inside the

opening in the corner worksurface.

Starting with the large brackets on the

worksurface, tighten all bracket screws

completely (Figure 3).

Figure 2

Figure 3

splice

plates

corner

worksurface

worksurface

grommet

modesty panel

(transitional)

adjoining

rectangular

worksurface

#12 x 1"

screws

#12 x 1"

screw

large

bracket

small

bracket

#10 x / "

screw

1

2

#10 x / "

screw

1

2

washer

adjustment

knob

corner

worksurface

power/data

door

leg set

(end-of-run)

transitional

leg

adjustable

glide

leg plug

WorkZone with Power & Data - Assembly Instructions

power & data

module

Figure 3

keyboard pad