12

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

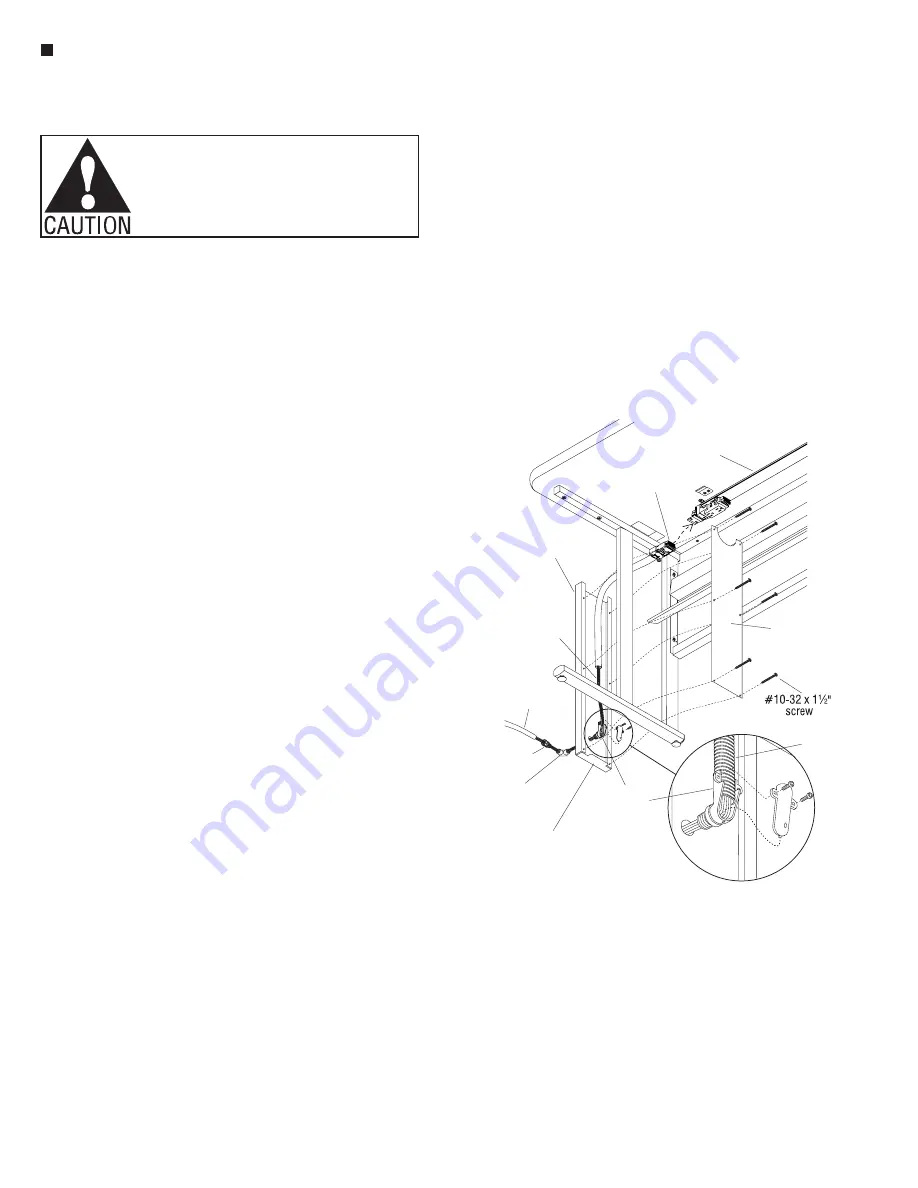

14. For 10-wire power infeed,

position the flexible conduit

between the vertical leg members

and plug the power infeed

connection into the 10-wire

harness under the table. Route

the uncased 10-wire through 90°

metal connector and through the

access hole of the infeed outer

wireway. Lay the oval conduit

flat (not on edge) into the bottom

half of the round 90° metal

connector. Assure the maximum

amount of conduit is inside the

fitting and connect the top half

of the fitting to the bottom. Use

screws supplied and assure that

the two sections are properly

connected, securely capturing

the flexible oval conduit

(Figure 5).

Note:

The conduit and

connector assembly has been UL

Listed in KI’s UL file to meet the

requirements of UL 1286

“Office Furnishings”. The 90°

metal connector is limited to the

following models: EGS Appleton

AC96 or Cooper Crouse 738.

Substitutions are not allowed.

15. Route the uncased 10-wire

through the 90° pulling elbow.

Next screw or thread the 90°

metal connector into the 90°

pulling elbow, sandwiching the

steel infeed panel. Slide the

liquid-tight connector onto the

10-wires and connect it to the

90° pulling elbow (Figure 5)

16. Set the infeed outer wireway up

against the outside of the vertical

leg members with support lip

resting on the foot of the leg.

Position the infeed inner wire

way up against the inside of the

vertical leg members. Fasten

infeed inner wireway to infeed

outer wireway with six #10-32 x

1½”screws (Figure 5).

17. Determine the appropriate length

for the liquid-tight conduit (to

power source) and cut it to size.

Slide the liquid-tight conduit

onto the 10-wires and connect

the conduit to the connector on

the elbow. Finally the liquid-tight

conduit may be fastened to a

junction box (customer supplied)

and the 10-wires can be cut to

size and connected to the power

source (Figure 5).

Important:

The Listed conduit

of the power infeed is intended to

be terminated with a commonly

available Listed conduit fitting

appropriate for the type and trade

size of the conduit.

Note:

The power infeeds

are to be connected to the

power source by a qualified

electrician who must also check

the electrical integrity of the

finished system. These steps are

intended as a guideline for the

installation.

18. The power/data door that is

attached to the modesty panel

snaps onto the two pre-installed

door clips at the underside of

the worksurface. The S-shaped

power/data divider that was

installed into the power/data

door is in place to separate

power from data lines (optional).

Note: This channel is not

to be used for routing

extension cords. Power

supply cords are not to be

routed across or through

more than one complete

unit/worksurface.

Data lines

can be run through worksurface

grommets and exit through

knockout in infeed outer wireway

or notch on inside of center

vertical wireway. Snap the power/

data door to the door clips when

power and data lines have been

run.

WorkZone

®

Desks - 24”, 30” x 30” through 54” Tops with Power & Data

Assembly Instructions

10-wire

harness

power infeed

infeed

inner

wireway

infeed

outer

wireway

uncased

10-wire

liquid-tight

connector

liquidtight conduit

(to power source)

90 pulling elbow

o

round

90 metal

connector

o

support lip

oval

flexible

conduit

Figure 5