1. Unscrew and remove the expansion tank filler cap

1

.

2. Position a receptacle beneath the water cooler drain point (accessible through a hole in the

floor panel).

3. Connect a suitable drain hose

7

to the radiator quick-release coupling

6

.

4. Lead the hose through the hole in the floor panel and into the receptacle, securing it in place.

5. Open the shut-off valve

5

and catch the draining coolant.

6. Close the shut-off valve and remove the drain hose.

7. Screw on the filler cap.

8. Close the access door.

Draining the coolant (closed floor pan - stationary machine):

Compressor cooling oil and engine coolant drain lines are led to a central point outside the ma‐

chine on stationary machines and machines with closed floor pan. The cooling oil is drained via a

pipe which is screwed into the drain opening of the cooler and closed with a shut-off valve. The

pipe is sealed with a screwed sealing plug at the drain end.

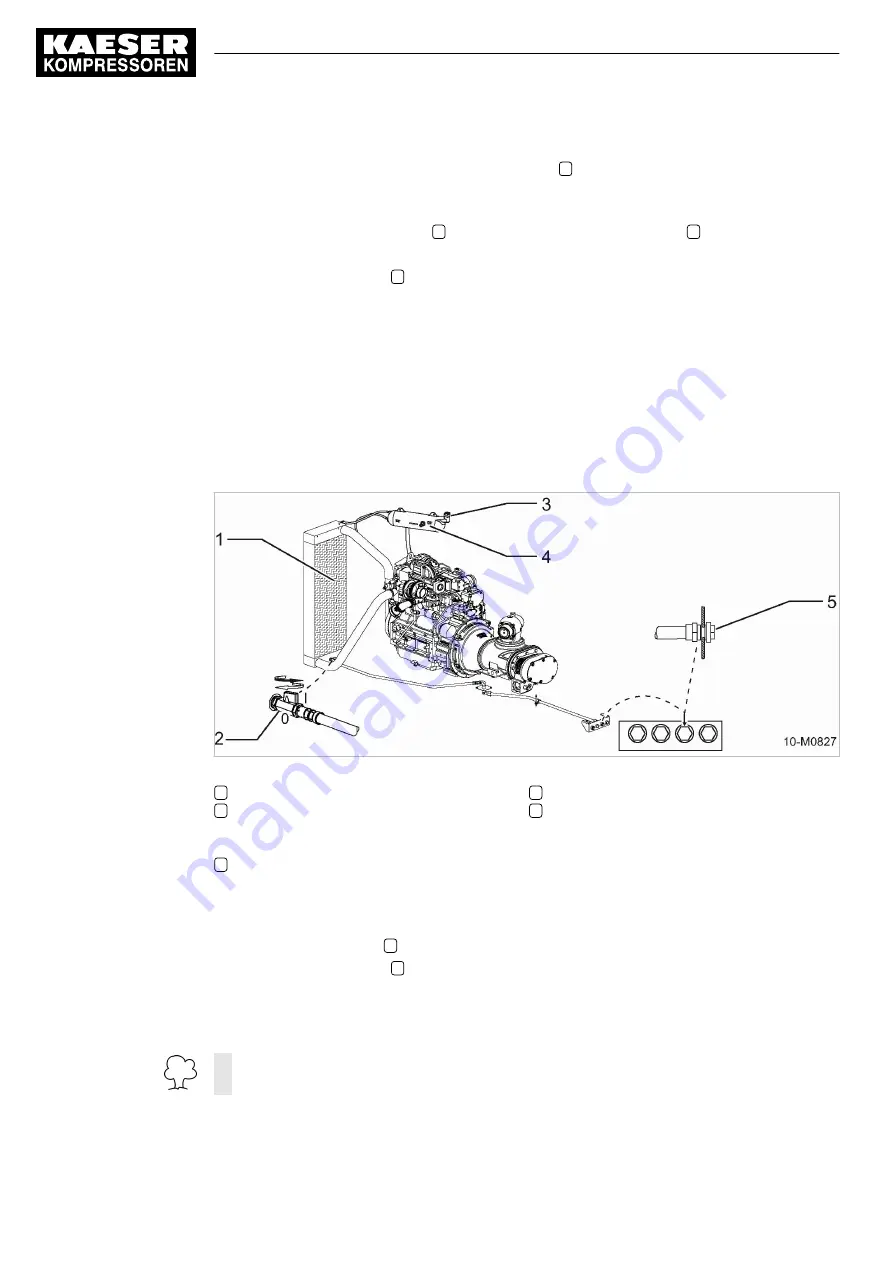

Fig. 38 Draining the coolant from the radiator (closed floor pan - stationary machine)

1

Radiator

2

Shut-off ball valve

I – open

0 – closed

3

Filler cap

4

Coolant expansion tank

5

Screwed sealing cap - coolant drain

1. Unscrew and remove the expansion tank filler cap.

2. Position a receptacle beneath the drainage location of the water cooler.

3. Unscrew the filler plug

5

at the coolant drain.

4. Open the shut-off valve

2

at the water cooler and catch any draining coolant.

5. Close the shut-off valve and replace the screwed sealing cap.

6. Screw in the filler cap.

7. Close the access door.

➤ Dispose of used coolant in accordance with environmental protection regulations.

Further information The operating manual supplied by the engine manufacturer provides further information on coolant

change and cleaning the cooling system.

10 Maintenance

10.3 Engine maintenance

90

Service manual Portable compressor

M122

No.: 9_6974 20 E

Option oe, sc, si

RAMIRENT