johNSoN coNtroLS

2-42

ForM 102.20-N1 (1109)

installation

ElECtRiCAl inStAllAtiOn

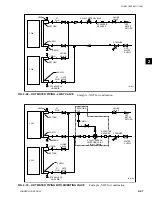

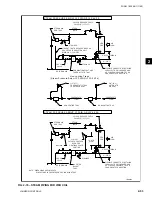

1. Follow the wiring diagram on the inside of the

terminal box.

2. Supply connections must be made with copper

wiring rated for 75° C minimum.

3. If supply connections are for 250 volts or greater,

all wiring must be insulated for 600 volts.

4. When making line connections to heater element

terminals FOR FINNED TUBULAR HEATERS

ONLY, apply a 1/4" wrench to flat section of termi

-

nal immediately below threads. Otherwise damage

to terminal may result.

5. Supply conductors for heaters rated less than 50

KW, must be sized at 125% of rated load. On heat

-

ers rated 50 KW and more, the supply conductors

may be sized at 100% of rated load, if indicated

on the wiring diagram. The line current for either

a single or three phase load is calculated as fol-

lows:

Single phase line Current =

Kw x 1000

voltage

three phase line Current =

Kw x 1000

voltage x 1.73

6. The following table shows the maximum current

for 75 °C copper wire with not more than 3 con

-

ductors in a raceway. It is based on the National

Electrical Code Table 310-16. The amperages

shown are for 125% and 100% wire sizing. If there

are more than 3 conductors in a raceway, derate

these amperages per Table 310-15(b)(2)(a).

MAXIMUM CURRENT FOR COPPER WIRING

AMPS

WiRE

SiZE

AWg/

MCM

AMPS

WiRE

SiZE

AWg/

MCM

AMPS

WiRE

SiZE

AWg/

MCM

125%

100%

125%

100%

125%

100%

12

14

80

100

3

184

230

4/0

16

12

92

115

2

204

255

250

24

10

104

130

1

228

285

300

40

8

120

150

0

248

310

350

52

65

6

140

175

2/0

268

335

400

68

85

4

160

200

3/0

304

380

500

7. When connecting heaters with more than one stage,

wire stage No. 1 so that it is the first stage on and

the last stage off.

8. The heater must be wired so that it cannot operate

unless air is flowing over it. This can be accom

-

plished by using a built-in airflow switch and a

remote interlock.

See the accompanying wiring

diagram for the method used with this heater and

provide appropriate interlock wiring as illustrated.

This diagram will be located inside of the electric

heater control panel.

9. If not supplied as part of this heater, install a

line disconnect switch or main circuit breaker in

accordance with the National Electrical Code.

Depending upon the heater’s location and acces-

sibility, a built-in disconnect switch may meet this

requirement.

10. All electrical connections in the heater, including

both field and factory made connections, should be

checked for tightness before operating the heater.

In addition, after a short period of operation, all

connections should again be checked for tight-

ness.

11. If heater is wired to a heating / cooling thermostat,

use a thermostat with isolating circuits to prevent

possible interconnection of Class 2 outputs.

12. If the heating elements are divided into several

sections with resistance wire between two or more

sections, maximum KW per sq. ft. should be cal

-

culated as follows:

number of heated sections x

area of one heated section

heater nameplate Kw

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...