3-5

johnson controls

ForM 102.20-n1 (1109)

3

Check Operation of Dampers

Ensure unit will not operate with all dampers closed.

Linkage design and/or damper linkage may not be

provided by Johnson Controls. Airflow control

dampers may be operated with pneumatic or electric

actuator/controllers.

Prior to occupancy, test ventilation sys-

tem to ensure that outdoor air dampers

operate properly in accordance with

the system design.

Airflow Control Dampers

Many combinations of damper sizes are available to

control the flow, the mixing of return air and outside

air in the air inlet section of the unit may be supplied

as follows:

• One hundred percent outside air, 100% return

air.

• One hundred percent outside air, 0% return air.

• Zero percent outside air, 100% return air.

• Economizer Section - 100% outside air, 100%

return air, 100% exhaust air or mixed air.

On dampers with actuators, intercon-

necting damper linkage is only pro-

vided when selected by Sales.

Dampers, actuators, controls and link-

age must be checked prior to applying

power to the operators making sure

nothing will obstruct the operation of

the dampers. Do not overdrive damper

actuators as this may cause damage to

the dampers.

Return air dampers may be closed for

shipping. Loosen actuator or crank

arm on jackshaft, open dampers, and

retighten actuator or crank arm. Field

is responsible for adjustments.

IAQ

START-UP

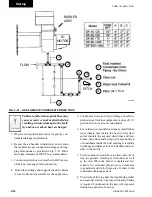

Temporary Operation: This equip-

ment should not be operated until after

complete Start-up as outlined in this

guide. Do not allow the unit to run

on temporary power that is not reliable

and could be off/on periodically or

rapidly. Also, protect it from irregular

voltages and surges.

We strongly recommend the startup

technician use the checklist provided

and record the gathered information

in the appropriate fields. If there are

any specific questions refer to the

document list on the checklist. Also,

at the end of Section 3 is located a list

of references for various check points

on the checklist (Inspection Require

-

ments). This is a guide to "How To"

information in this and other docu-

ments.

Filter media must be installed prior

to Start-up. Use media provided or

temporary media that will adequately

protect the components in the air

stream and duct system.

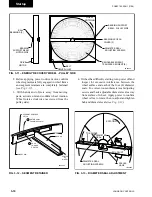

Check Operation of Fans

1. Energize power to the unit disconnect switch.

2. Verify correct voltage, phase and cycles.

3. Energize fan motor(s), briefly (bump) and check

for correct fan rotation.

If rotation is incorrect:

1. On three-phase equipment reverse any 2 motor

leads at the load side of last starter component.

2. On single-phase equipment, follow wiring dia-

gram on motor housing or inside motor terminal

box.

3. Re-check for correct fan rotation.

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...