2-3

johNSoN coNtroLS

ForM 102.20-N1 (1109)

2

Curb Assembly and installation instructions

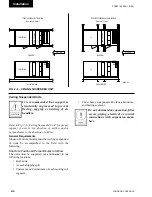

See Fig. 2-2

1. Unpack shipping package, layout pieces and

parts according to the exploded views and check

against Bill of Materials.

2. Layout all channel pieces as shown. Make certain

that all channel tabs are located on inside of mat-

ing channel

Make certain that all curb walls ac-

cessories and flanges, which may

have been distorted in handling, are

straightened before assembly.

3. Attach curb walls together to form rectangular

perimeter as shown, leaving bolts loose.

After the curb is set in place, ensure

proper consideration has been given

to the air duct openings through the

roof.

4. The curb installation drawing (see Fig. 2-2)

shows a gasket that is mounted between the curb

and the unit. This gasket is shipped with the curb

parts. Install the curb gasket before setting the

unit on the curb. The gasket forms an air seal

between the unit and the curb and serves as a

dampener, preventing metal-to-metal contact

between the unit and curb. However, the gasket

should not be used as a vibration isolator where

the prevention of noise and vibration transmis-

sion into the building is critical.

When unit is shipped in sections, the

curb gasket is to be replaced with caulk

provided by contractor.

5. After verifying curb is square and level, tighten

all bolts and then anchor as appropriate.

If bolts are tightened after anchoring,

curb will be pulled, twisted and torqued

out of square.

6. Pipe Chase Curb Assembly - once curb is square

and level mark the exact location for the pipe

chase curb. Drill and assemble.

Pipe Chase Curb location:

Unit submittal drawing package has

a Johnson Controls curb drawing

showing dimensions of curb and pipe

chase.

7. The curb should be insulated and roofed as re-

quired. Refer to SMACNA for counter flash.

Steel Frame

When a steel frame is used to support the unit, it must

be level, flat without uneven steel frame joints, and

support the unit around the full perimeter. As a general

rule, cross members should be placed every 96" in

addition to every shipping split.

indoor units (Site Prep)

Concrete pads often are not as flat

as they should be. Shimming and/or

grouting may be necessary. This is to

ensure the unit base is on a perfectly

flat plane.

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...