johNSoN coNtroLS

2-58

ForM 102.20-N1 (1109)

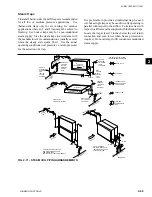

installation

When the condensing unit has three compressors

per circuit, two coil circuits should be used for each

refrigerant circuit (Fig. 2-87). Each coil circuit must

have a dedicated TXV and distributor to handle one coil

circuit and the LLSV should be sized to handle the full

capacity of the refrigerant circuit. The hot gas bypass

line should be connected to all of the distributors in the

coil circuit.

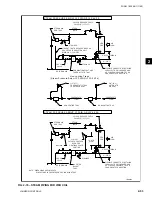

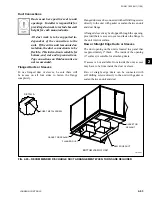

In the case of a stacked coil with four coil circuits piped

to a condenser with six compressors, the coil circuits

would be face-split and interlaced with two interlaced

circuits on the lower coil section and two on the upper

(Fig. 2-89).

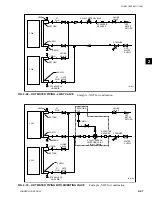

Fig. 2-84 – OnE COil CiRCuit PER

REFRigERAnt CiRCuit

100% Capacity

dx Coil

condensing Unit

LD09148

Fig. 2-85 – tWO COil CiRCuitS PER

REFRigERAnt CiRCuit

dx Coil

condensing Unit

compressor #1

compressor #2

txv

LLSv

txv

LD09149

dx Coil

condensing Unit

compressor #1

compressor #2

txv

LLSv

LLSv

txv

LD09150

Fig. 2-86 – dO nOt uSE thE ABOVE

COnFiguRAtiOn.

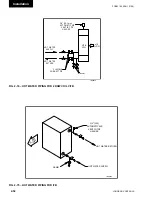

Fig. 2-87 – thREE COMPRESSOR YCul

LD09151

DX Coil

Condensing Unit

Compressor #1

Compressor #3

Feeds both Circuits

Compressor #2

TXV

LLSV

TXV

dx Coil

condensing Unit

compressor #1

compressor #3

Feeds both Circuits

compressor #2

txv

LLSv

LLSv

txv

LD09152

Fig. 2-88 – dO nOt uSE thE ABOVE

COnFiguRAtiOn.

When sizing TXV's, each TXV must

be sized for the refrigerant circuit

tonnage divided by the number of

DX coil liquid distributors. The TXV

should be equal to or smaller than the

calculated value.

The first three compressors (

see Fig. 2-89

) would

be tied into LLSV1, TXV1 and TXV2. This would

provide full-face control of the coil at even the lowest

cooling loads. Both distributors on each of the coil

circuits would include auxiliary side connectors for

HGBP.

The second set of 3 compressors would be tied into

LLSV2, TXV3 and TXV4 to maintain full-face control

at higher loads.

Reference Form 050.40-ES3 Section 9

for compressor staging solutions.

The more control stages used, the more precise

the control of the air temperature will be. Smaller

incremental changes in capacity will result in a more

consistent DX coil leaving air temperature. This will

eliminate temperature swings in the conditioned space

and improve the comfort level, but more importantly, a

consistent space temperature is crucial to many process

applications. The smaller changes in capacity that

result from using a greater number of control stages

will also extend equipment life. The most important

thing to remember is to maintain full-face control of

the coil at all cooling loads. When row split coils are

used, make sure that the first LLSV is energized with

the last coil circuit in the leaving air stream. This is

always the last one de-energized too.

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...