johNSoN coNtroLS

1-2

ForM 102.20-N1 (1109)

Pre-installation

Off-loading

Proper rigging and handling of the equipment is

mandatory during unloading and setting it into position

to retain warranty status.

Care must be taken to keep the unit in the upright

position during rigging and to prevent damage to the

air and watertight seams in the unit casing. Prevent

unnecessary jarring or rough handling.

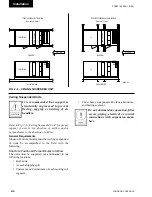

For lifting air handling units with lifting lugs or corner

connectors; proper spreader bars and hoisting line

must be used when rigging to prevent damage to the

unit casing

(see Fig. 1-1).

When lifting long units a

special system must be used to insure a minimum 60°

angle between lifting lug and spreader bar/frame

(see

Fig. 1-2 and Table 1-1).

It is also mandatory that an

experienced and reliable rigger be selected to handle

unloading and final placement of the equipment. The

rigger must be advised that the unit contains internal

components and that it be handled in an upright

position. Care must be exercised to avoid twisting the

equipment structure.

Refer to the submittal for the section

weights.

All lifting lugs must be used to avoid

damage to unit. If unit does not have

lifting lugs, use bottom corner connec-

tors and intermediate raceway lifting

lugs. Do not use top corner connec-

tors.

Unit section weights are furnished on the job submittal.

Due to the variance in weight of each unit design, it is

not possible to list unit weights in this instruction. The

submittal must be referred to when selecting a crane

for rigging and figuring roof weight loads. Contact

your Johnson Controls Sales representative if you have

any questions regarding unit weights.

Crane And Spreader Bars

See Fig's 1-1 and 1-2.

Fork lift

Forklifts should not be used to off-load air handlers

except in special circumstances. If moving air handling

equipment with a fork lift or similar means becomes

necessary, always make sure the lifting forks are long

enough to reach from the fork truck to the opposite side

and slightly beyond. It is helpful to leave the shipping

blocks attached to the bottom of the equipment until

in its final location. There is no structural support

under the equipment except what is visible from the

perimeter.

Come-A-longs or Power Pull

See Fig1-3 below

Fig. 1-3 – tYPiCAl COME-A-lOng tYPES

LD09613

tABlE 1-1 - SPACing REQuiREMEntS FOR

OFFlOAding lOng unitS

unit ht.

MAX. LIFTING

lug SPACing

Min. liFting

StRAP lEngth

≤

72"

120"

120"

> 72"

192"

192"

Summary of Contents for YORK SOLUTION LD09624

Page 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...