JOHNSON CONTROLS

FORM 160.75-O1 (309)

26

maintenance

Vacuum dehYdration

To obtain a sufficiently dry system, the following instruc

-

tions have been assembled to provide an effective method

for evacuating and dehydrating a system in the field. Al

-

though there are several methods of dehydrating a system,

we are recommending the following, as it produces one of

the best results, and affords a means of obtaining accurate

readings as to the extent of dehydration.

The equipment required to follow this method of de-

hydration consists of a wet bulb indicator or vacuum

gauge, a chart showing the relation between dew point

temperature and pressure in inches of mercury (vacuum),

(See Table 2) and a vacuum pump capable of pumping

a suitable vacuum on the system.

operation

Dehydration of a refrigerant system can be obtained

by this method because the water present in the system

reacts much as a refrigerant would. By pulling down

the pressure in the system to a point where its satu-

ration temperature is considerably below that of room

temperature, heat will flow from the room through the

walls of the system and vaporize the water, allowing

a large percentage of it to be removed by the vacuum

pump. The length of time necessary for the dehydration

of a system is dependent on the size or volume of the

system, the capacity and efficiency of the vacuum pump,

the room temperature and the quantity of water present

in the system. By the use of the vacuum indicator as

suggested, the test tube will be evacuated to the same

pressure as the system, and the distilled water will be

maintained at the same saturation temperature as any

free water in the system, and this temperature can be

observed on the thermometer.

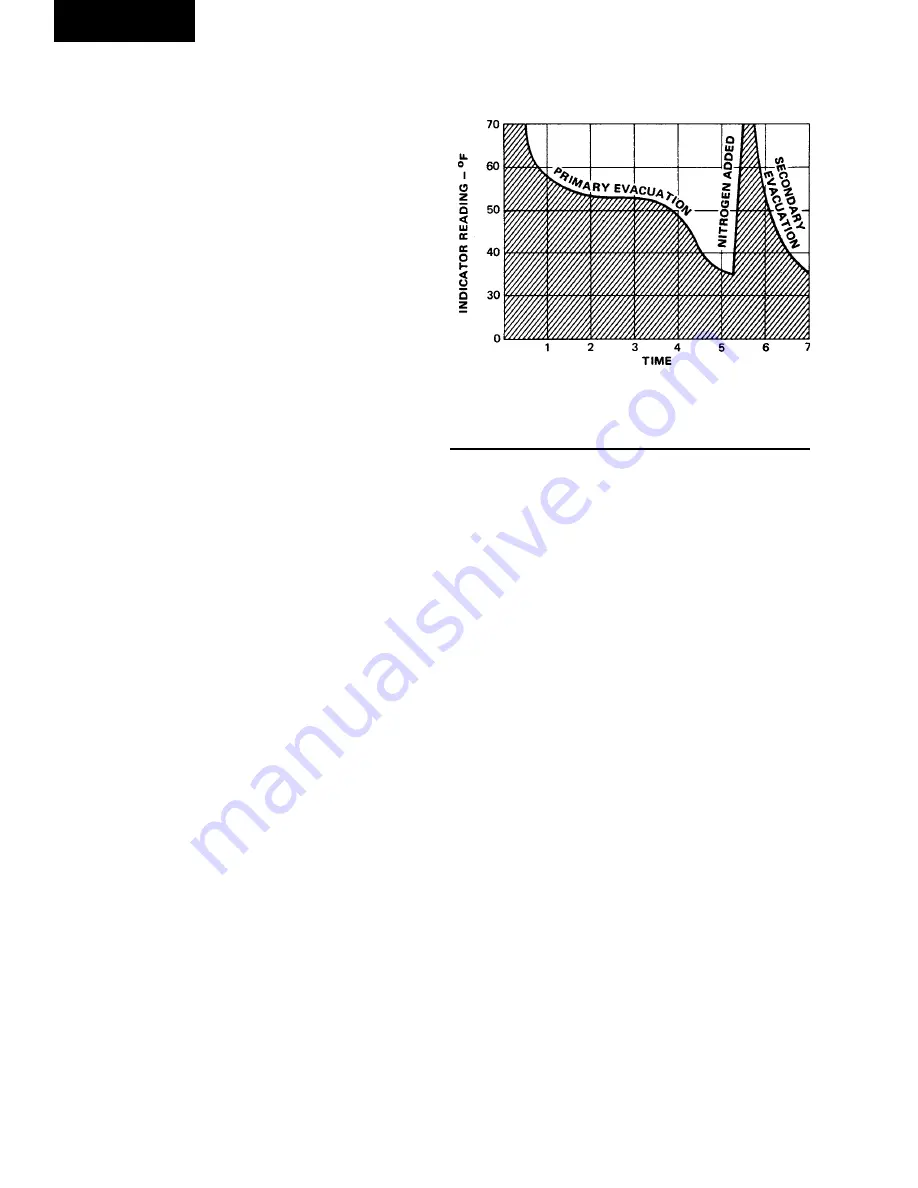

If the system has been pressure tested and found to be

tight prior to evacuation, then the saturation temperature

recordings should follow a curve similar to the typical

saturation curve shown as FIG. 10.

The temperature of the water in the test tube will drop as

the pressure decreases, until the boiling point is reached,

at which point the temperature will level off and remain

at this level until all of the water in the shell is vaporized.

When this final vaporization has taken place the pressure

and temperature will continue to drop until eventually

a temperature of 35°F (1.6°C) or a pressure of 5 mm

Hg. is reached.

When this point is reached, practically all of the air has

been evacuated from the system, but there is still a small

amount of moisture left. In order to provide a medium

for carrying this residual moisture to the vacuum pump,

nitrogen should be introduced into the system to bring it

to atmospheric pressure and the indicator temperature will

return to approximately ambient temperature. Close off

the system again, and start the second evacuation.

The relatively small amount of moisture left will be car-

ried out through the vacuum pump and the temperature

or pressure shown by the indicator should drop uni-

formly until it reaches a temperature of 35°F (1.6°C)

or a pressure of 5 mm Hg.

When the vacuum indicator registers this temperature

or pressure, it is a positive sign that the system is evac-

uated and dehydrated to the recommended limit. If this

level cannot be reached, it is evident that there is a leak

somewhere in the system. Any leaks must be corrected

before the indicator can be pulled down to 35°F or 5

mm Hg. in the primary evacuation.

During the primary pulldown, keep a careful watch on

the wet bulb indicator temperature, and do not let it fall

below 35°F (1.6°C). If the temperature is allowed to fall

to 32°F (0°C), the water in the test tube will freeze, and

the result will be a faulty temperature reading.

fig. 10 –

SATuRATION CuRVE

LD00474

Summary of Contents for York MaxE YK Series

Page 2: ...Page 2 of 2 ...

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 135: ...JOHNSON CONTROLS FORM 160 75 O1 309 36 SI metric conversion ...

Page 137: ...JOHNSON CONTROLS FORM 160 75 O1 309 38 NOTES ...

Page 138: ...FORM 160 75 O1 309 39 JOHNSON CONTROLS NOTES ...