MAN1106-07-EN_XL+_UserManual

M a y 6

t h

, 2 0 2 0

P a g e 55 | 192

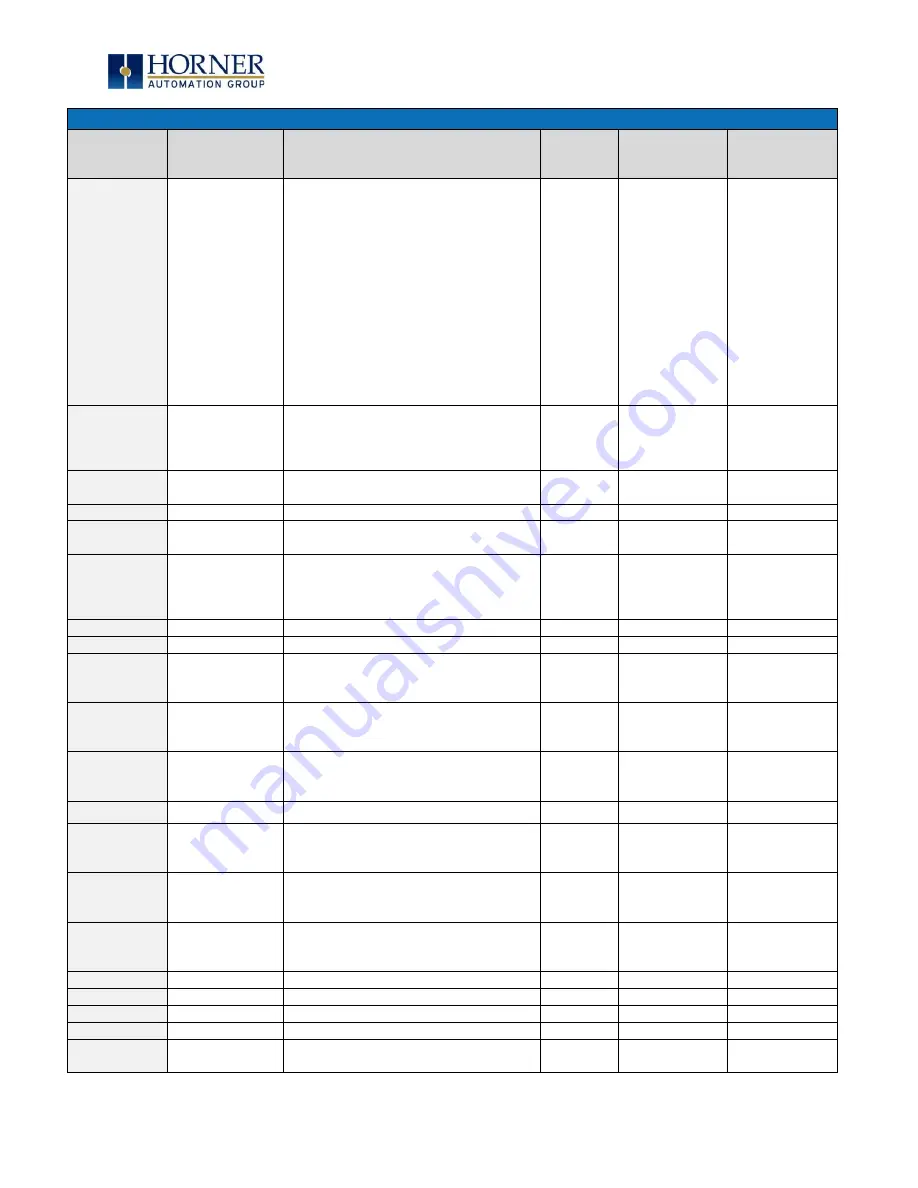

Table 6.3

–

%SR Registers

–

Master %SR Table

Register

Default I/O

Name

Description

Min-Max

Values

Program

(Read/Write)

Display

(Read/Write)

Up = 30

Down = 31

Shift = 32

Soft Key 1 = 34

Soft Key 2 = 35

Soft Key 3 = 36

Soft Key 4 = 37

Soft Key 5 = 38

Soft Key 6 = 39

Soft Key 7 = 40

Soft Key 8 = 41

Release = 255 (Keys pressed since

power-up but not currently)

*Excludes RCC Units

%SR57

LCD Backlight Dimmer Register

0-100 = 0% to 100% On

100-255 = 100% On

*Excludes RCC Units

0 to 255

Read/Write

Read/Write

%57.16

Temporarily disable Screen Saver

*Excludes RCC Units

Read/Write

Read/Write

%SR58

USER_LEDS

User LEDs

Read/Write

Read/Write

%SR59

Engine Build Number (Only last three

numbers displayed)

Read Only

Read Only

%SR60

Build Option

Build Test = 0

Build Beta = 1

Build Product = 2

0 to 2

Read Only

Read Only

%SR61

NUM_IDS

Number of CsCAN Network IDs

Read Only

Read Only

%SR62-100

Reserved

%SR101.3

WebMI License Details

–

WebMI server

status

*XLEe, XLTe, X2, X4, & X7 only

Read Only

Read Only

%SR101.4

WebMI License Details

–

WebMI user

logged in status

*XLEe, XLTe, X2, X4, & X7 only

Read Only

Read Only

%SR101.8-

101.16

WebMI License Details

–

Number of

users

*XLEe, XLTe, X2, X4, & X7 only

Read Only

Read Only

%SR102-107

Reserved

%SR108

WebMI License Details

–

Number of

webpages

*XLEe, XLTe, X2, X4, & X7 only

Read Only

Read Only

%SR109

WebMI License Details

–

Number of

datapoints

*XLEe, XLTe, X2, X4, & X7 only

Read Only

Read Only

%SR110-112

WebMI License Details

–

Expiry date of

WebMI license

*XLEe, XLTe, X2, X4, & X7 only

Read Only

Read Only

%SR113-130

Reserved

%SR131-135

OCS Model: ASCII, 10 characters

Read Only

Read Only

%SR136

Communication Download Timeout

Read Only

Read Only

%SR137

Communication Idle Timeout

Read Only

Read Only

%SR138-148

Reserved