3-21

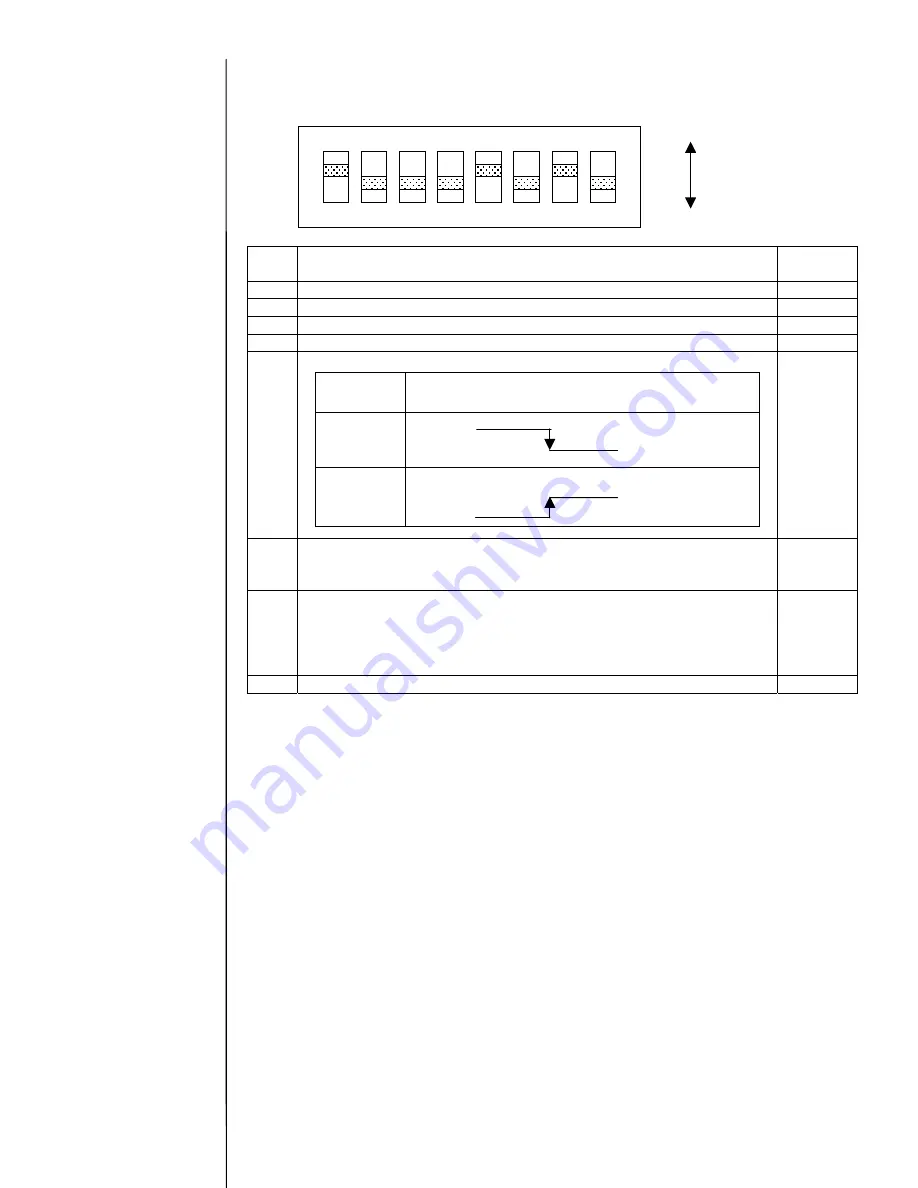

[Setting of switch]

・

Setting of switch

[SW1]

SW1

Description

Standard

setting

Bit 1 Sets host communications (Set to ON)

ON

Bit 2 Sets host communications (Set to OFF)

OFF

Bit 3 Reserve (Set to OFF)

OFF

Bit 4 Reserve (Set to OFF)

OFF

Bit 5 Sets the polarity of strobe signal transmitted from host.

ON

Bit 6 Switches the filter constant of strobe signal (capacitance).

ON

:

0.047(uF)

+

2.2(uF)

OFF

:

0.047(uF)

OFF

Bit 7 Switches the power supply for input signal.

Set to ON when using the IJP internal power supply (12 V).

Set to OFF when using an external power supply

(Connect the external power supply (12- 24 V) to pin 1 of

terminal board (TB1).)

ON

Bit 8 Reserve (Set to OFF)

OFF

[Notes for replacement:]

- Be sure to turn power off when replacing the EZJ99 board.

- Save the data on memory card by using the copy data function before replacing the EZJ99

board, and be sure to recover the data after replacement.

As the operation management, the parts usage time management, password setup and the

unit information are not backed up by the copy data function. Set them again.

- Set the SW1.

OFF

ON

1

2

3

4

5

6

7

8

ON

Setting

Photo coupler operation

(voltage level at TB1 pin 12)

ON

O

FF

OFF

As for the copy data

function, see “2.9

Backup”.

Summary of Contents for PXR

Page 1: ...Service Manual HITACHI Printer Model PXR Revision December 2008 Version C ...

Page 80: ...3 17 3 17 Circuit diagram of EZJ95 ...

Page 215: ...8 2 8 1 2 Circulation system diagram PXR P ...

Page 216: ...8 2 Air system diagram PXR P 8 3 ...

Page 217: ...8 4 8 3 Electrical Connection Diagram 8 3 1 Electrical Connection Diagram PXR D ...

Page 218: ...8 5 8 3 2 Electrical Connection Diagram PXR H ...

Page 219: ...8 3 3 Electrical connection diagram PXR P 8 6 ...