6-14

6.8 Head base Replacement Procedure

When damaging the head base, the head base must be replaced. Perform it by the

following procedure.

(1) Remove all of the covers described in the item 6.1.

(2) Remove the nozzle described in the item 6.2.

(3) Remove the deflecting base described in the item 6.3.

(4) Remove the sealing valve described in the item 6.5.

(5) Remove the heating unit described in the item 6.6.

(6) Remove the gutter base described in the item 6.7.

(7) Remove the FG and NH sponges.

(8) Remove the soldering of the APH sensor board and the signal wire.

(9) Unscrew the APH sensor board setscrew.

(10) Unscrew the fastening screw between the head base and the head cable, and

remove the head base.

(11) Attach a new head base.

“Caution”

(A) Do not mix up lead wires and tubes which each is disposed on the

front face (nozzle side) and the back face (high voltage cable side).

Front face: ink-furnishing tube (E), makeup ink tube (R), circulation tube (J), air

purge.

Back face: excitation signal wire (pull it out from the head base opening to the

front face),

G, sealing valve feeder wire, recovery tube, APH signal

wire, video signal wire, heater feeder wire, cover SW signal wire,

EZJ98 board signal wire, high voltage feeder wire

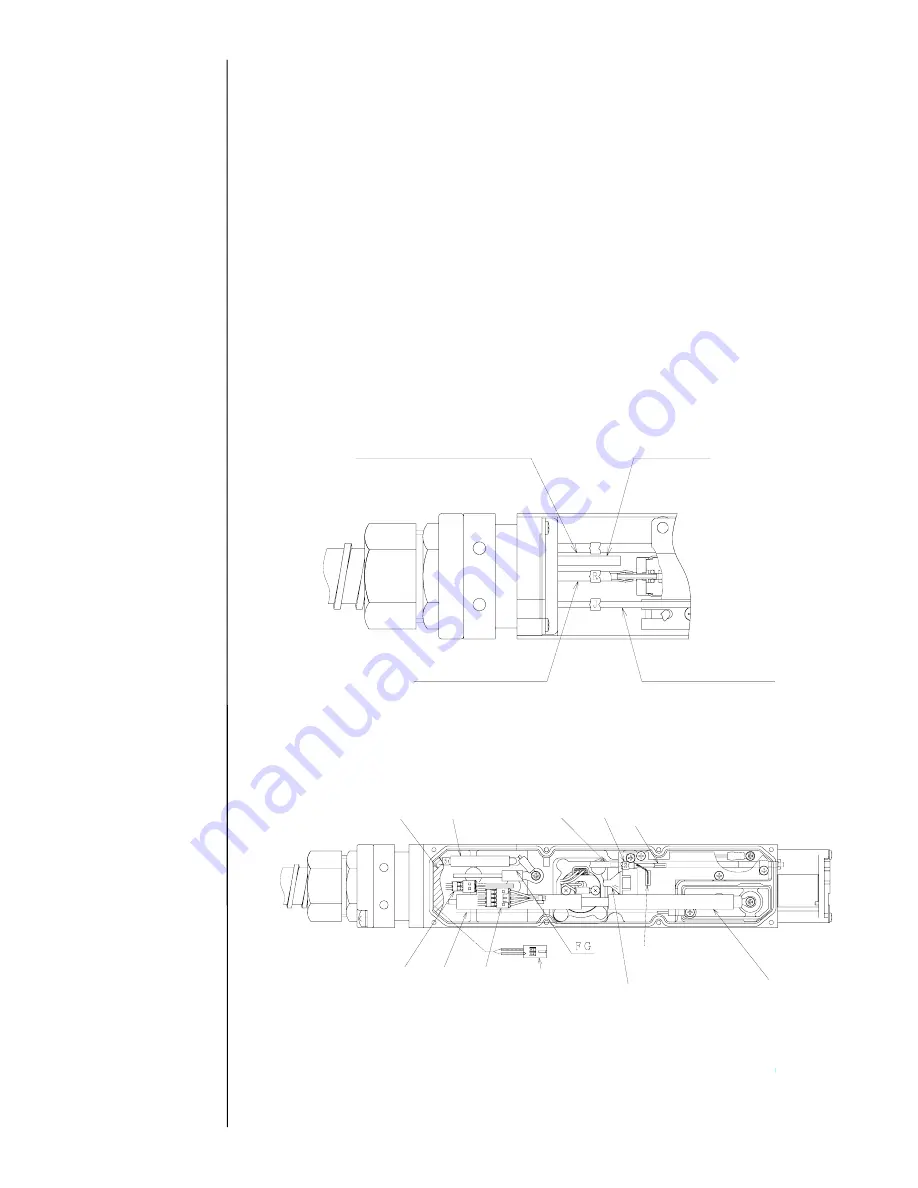

E

Ink-furnishing tube (E)

Air purge

Circulation tube (J)

Makeup ink tube (R)

High

voltage

GND side

soldering

EZJ98 CN1

signal wire

Cover SW

Heater

Video

Sealing

valve

Signal side

soldering

APH

Recovery

Excitation

Sponge

Summary of Contents for PXR

Page 1: ...Service Manual HITACHI Printer Model PXR Revision December 2008 Version C ...

Page 80: ...3 17 3 17 Circuit diagram of EZJ95 ...

Page 215: ...8 2 8 1 2 Circulation system diagram PXR P ...

Page 216: ...8 2 Air system diagram PXR P 8 3 ...

Page 217: ...8 4 8 3 Electrical Connection Diagram 8 3 1 Electrical Connection Diagram PXR D ...

Page 218: ...8 5 8 3 2 Electrical Connection Diagram PXR H ...

Page 219: ...8 3 3 Electrical connection diagram PXR P 8 6 ...