PCL 600

Operators Manual

v 2.0

61

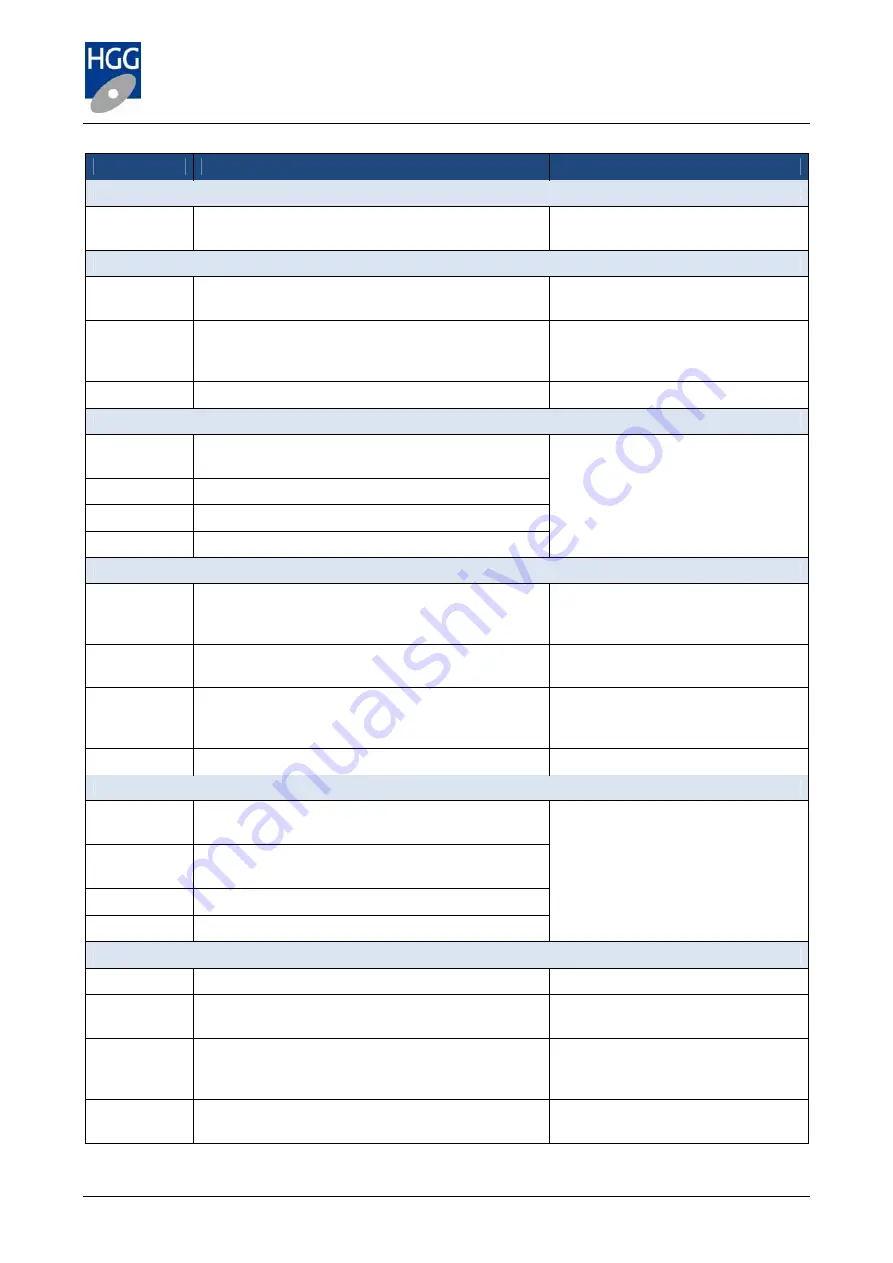

Error number

Error text

Problem/Reference chapter

Staubli robot

003:010:029

Error sending Staubli Arc control

Move robot to safe, this will re-send

the Arc control data

Plasma tool ignition

003:012:301

Plasma pilot/main arc timeout

Check the nozzle, clean if

necessary and try again.

003:012:302

Plasma main arc timeout after pilot arc

Check the plasma unit for an error.

Check the nozzle, clean if

necessary.

003:012:303

Plasma unit error during ignite

Check the plasma unit for an error.

Data collector

003:025:001

Data Collector returned no result. Data not

collected.

The data collector keeps a record of

machine activity. Messages marked

with * are notifications not errors.

For the remaining messages, check

the path (file location).

003:025:002

Purging archive ... (older than <number> days)*

003:025:003 Purged

archive*

003:025:005

Data Collector, settings loaded*

ProCAM

005:002:006

Error starting ProCAM

First check the path the try again.

The default path is C:\Program

Files\HGG\ProCAM

005:002:008 License not found

Insert your HASP key (see ProCAM

manual for further help)

005:002:009

License lost, shutting down after <number>

seconds

Insert key. If the key is inserted,

check the connection, remove and

replace the key.

005:002:010 License

restored

Notification.

REA inkjet printer controller

005:062:001

Error communicating with printer on port

<numbered port>

Check the printer connection and try

again. If the problem continues,

contact HGG

005:062:002

Error sending purge command, communication

error

005:062:003

Error sending text to printer

005:062:004

Error sending line to printer

Settings

009:001:001

Unable to open settings file: <named file>

Check the path and the file name.

009:001:002

File <named file> does not exist. Do you want to

create this file?

File not found, check path. If it is a

new setting, create the file.

009:001:003

Unable to create settings file: <named file>

There is a security block on some

essential files, these files may not

be changed.

009:001:004

Name change not allowed

The name of this setting may not be

changed.