6 - Maintenance

150

9.

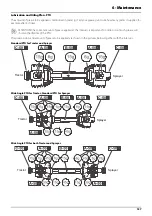

Check the brake drum diameter (K) and lining thickness (L). Replace if worn.

Max. wear rates on brake components:

•

Max. drum diameter (K): 302 mm (Small drums)

•

Max. drum diameter (K): 402 mm (Large drums)

•

Min. lining thickness (L): 2.0 mm

±

WARNING! The specified minimum lining thickness (L) is the absolute minimum, which must never be exceeded.

Replace the parts, if they would reach the above dimensions before the next service inspection.

±

WARNING! Renewal of brake linings or brake drums must be done for both sides at the same time.

μ

ATTENTION! If the brake drum must be removed from the wheel hub, a hydraulic press is required to press the wheel

studs out.

10.

Remove the clevis pin between the air diaphragm cylinder and the

brake cam lever.

11.

Remove the cotter pin (G), castle nut (F) and the brake shoe anchor

bolt (H), and slide the brake shoes over the cam. Twist the pair of

brake shoes to remove the shoe return springs (I). Replace the

brake shoes, if the linings are worn.

12.

Apply a small amount of copper paste on moving parts and

reassemble the brake shoes and shoe return springs (I).

±

WARNING! Do not get copper paste in contact with the brake

linings and drums.

13.

Fit the shoe assembly with the anchor bolt (H) first. Then pull the

shoes away from each other and slide them over the cam

afterwards. Tighten the anchor bolt castle nut (F) again, and fit a

new cotter pin (G).

14.

Check roller bearings for discolouration and wear. Replace if worn

or damaged.

15.

Assemble drum (D) and bearings (E) using a new sealing ring (J).

16.

Fill the hub and bearings with new grease, before fitting them to the wheel axle.

±

WARNING! Do not get oil or grease in contact with the brake linings and drums.

17.

Fit the castle nut (C). Rotate the brake drum (D) and tighten the castle nut (C), until a slight rotation resistance is felt.

18.

Loosen the castle nut (C) again, until the first notch is aligned with the cotter pin hole in the axle.

μ

ATTENTION! The shaft has a vertical and an horizontal cotter pin hole. Use the one first aligned with the notch when

loosening the castle nut.

19.

Fit a new cotter pin (B) and bend it to keep it in place.

20.

Fit the hub cap (A) to the hub. Slightly tighten the 6 bolts.

21.

Adjust the brakes as described in “250 Hours Service - Adjustment of Wheel Brakes” on page 147.

22.

Fit the wheel again and tighten the wheel nuts. See “Tightening Bolts and Nuts” on page 139 regarding torque wrench

setting. Tighten all bolts to half the specified torque at first, then tighten to the full specified torque.

23.

Tighten again after 10 hours of work. Check the torque every day, until it is stabilised.

24.

Repeat the steps for servicing the left wheel. Remember to place chocks on both sides of the right wheel.

±

WARNING! If you do not feel totally confident changing wheel bearings or brakes, then contact your HARDI dealers

workshop.

Summary of Contents for NAVIGATOR VPZ

Page 4: ...1 EU Declaration 4...

Page 72: ...3 Description 72...

Page 135: ...6 Maintenance 135 Lubrication Plan Boom Wings 10...

Page 174: ...6 Maintenance 174...

Page 182: ...7 Fault Finding 182...

Page 195: ...8 Technical Specifications 195 Hydraulic Diagrams Hydraulics for Boom of 21 24 Meters...

Page 196: ...8 Technical Specifications 196 Hydraulics for Boom of 27 28 Meters...

Page 198: ...8 Technical Specifications 198...

Page 204: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 N rre Alslev DENMARK...