6 - Maintenance

148

250 Hours Service - Hydraulic Brakes

Apply brakes to full pressure and inspect brake lines for damages or leaks. Replace damaged parts.

If the hydraulic brake lines have been dismantled, the hydraulic circuit must be vented afterwards:

1.

Have a helper to apply the brake.

2.

Loosen the brake hose at the left brake cylinder.

3.

The helper may continue applying the brake, until brake fluid without air bubbles comes out.

4.

Tighten the brake hose, before relieving the brake again.

5.

Repeat step 1-4 to vent the right brake cylinder.

±

WARNING! Always vent the circuit, if the hydraulic brake lines have been dismantled.

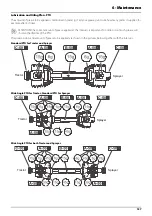

250 Hours Service - Air Brake Filters

1.

Clean the area around air filter(s) and disconnect air hose from the

tractor.

2.

Hold one hand under the filter housing, and pull out the retainer

clip (A). The filter cartridge assembly will be pushed out by the

springs inside the filter housing.

3.

Clean the filter cartridge. Use water and an appropriate detergent

or compressed air.

4.

Dry the parts and reinstall in the order shown. The O-ring should

be lightly lubricated with silicone grease before installation.

±

WARNING! Never dismantle the filter without having the tractor

disconnected and pressure relieved.

Summary of Contents for NAVIGATOR VPZ

Page 4: ...1 EU Declaration 4...

Page 72: ...3 Description 72...

Page 135: ...6 Maintenance 135 Lubrication Plan Boom Wings 10...

Page 174: ...6 Maintenance 174...

Page 182: ...7 Fault Finding 182...

Page 195: ...8 Technical Specifications 195 Hydraulic Diagrams Hydraulics for Boom of 21 24 Meters...

Page 196: ...8 Technical Specifications 196 Hydraulics for Boom of 27 28 Meters...

Page 198: ...8 Technical Specifications 198...

Page 204: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 N rre Alslev DENMARK...