-DA -21

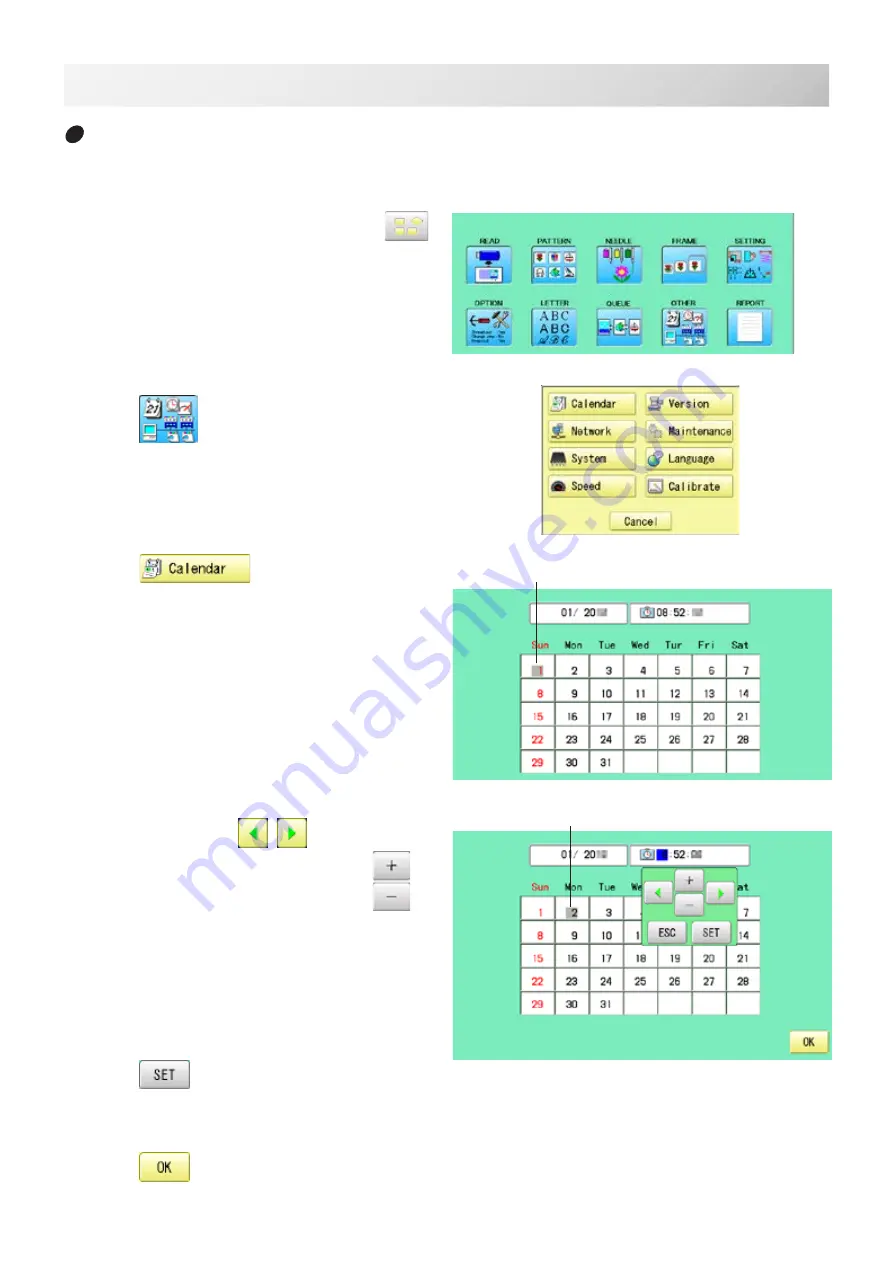

1. When the machine is stopped, press

.

2. Press

”OTHER”.

3. Press

.

Current year, month date and time is displayed.

4. Select year/month or time.

Press right /left of

to select the

setting point, and press up/down of

to

select the number.

To select the day,

select

the day of

calendar

directly.

5. Press

.

The date is fixed.

6. Press

to return to Menu mode.

Calendar and clock setting

Setting the calendar and clock lets the machine advise when oiling and other maintenance is

scheduled to occur.

TURNING THE MACHINE ON

5-2

3_6 RA01

Set day

Curren

t

day

Summary of Contents for HCH Plus

Page 2: ......

Page 127: ...D2 117 13 6 FRAME CONFIRMATION 20_5 NB01 11 Press Press to return to Drive mode...

Page 254: ...RA 110 26 3 BUILT IN FONT LIST 26_3 P401 Basic script Diacritic script...

Page 255: ...RA 111 26 3a BUILT IN FONT LIST 26_3a P401...

Page 300: ......

Page 314: ......

Page 341: ...HCH HCS HCD HCU ONE TOUCH FRAME 7 1 FOPC01 1 12 13 14 2 6 3 B 11 C 9 4 E A 3 4 D C 8 7 5 10...

Page 354: ......