1-15-96

96-8100

HAAS

AUTOMATION, INC.

47

MECHANICAL SERVICE

S E R V I C E M A N U A L

VF-S

ERIES

3. Go to PARAMETERS page of CRT and ensure PRE-CHARGE DELAY is set to 200. If not, do so at this time.

4. Execute a tool change. A banging noise will be heard as the tool release piston contacts the drawbar.

5. Turn the air pressure regulator ½ turn in. Execute a tool change and listen for the noise described previously. If it is

heard, repeat this step until no noise is heard. There should be no noise with or without a tool in the spindle.

CAUTION!

Only increase the pressure to the point where tool changes become obviously quiet. Any further pressure

increases are not beneficial. Excessive pressure to the pre-charge system will cause damage to the tool changer and

tooling in the machine.

Summary of Contents for VF-SERIES

Page 180: ...1 15 96 96 8100 177 TABLEOFCONTENTS TECHNICAL REFERENCE SERVICE M A N U A L VF SERIES ...

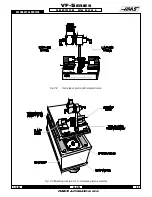

Page 235: ...96 8100 1 15 96 232 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 1 COLUMN ...

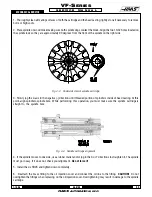

Page 237: ...96 8100 1 15 96 234 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 1 LEADSCREW ...

Page 239: ...96 8100 1 15 96 236 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 3 COLUMN ...

Page 241: ...96 8100 1 15 96 238 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 3 LEADSCREW ...

Page 245: ...96 8100 1 15 96 242 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS 3 4 2 1 ...