1-15-96

96-8100

197

TABLE OF CONTENTS

ELECTRICAL SERVICE

S E R V I C E M A N U A L

VF-S

ERIES

MAINTENANCE SCHEDULE

FOR THE VF-SERIES MILL

INTERVAL

MAINTENANCE PERFORMED

DAILY

3

Check coolant level.

3

Check way lube lubrication tank level.

3

Clean chips from way covers and bottom pan.

3

Clean chips from tool changer.

3

Wipe spindle taper with a clean cloth rag and apply light oil.

WEEKLY

3

Check Through the Spindle Coolant (TSC) filters. Clean or replace element if needed.

3

Check automatic dump air lines water trap for proper operation.

3

On machines with the TSC option, clean the chip basket on the coolant tank. Remove the

tank cover and remove any sediment inside the tank. Be careful to disconnect the coolant

pump from the controller and POWER OFF the control before working on the coolant tank.

Do this MONTHLY for machines without the TSC option.

3

Check air gauge/regulator for 85 psi.

3

For machines with the TSC option, place a dab of grease on the V-flange of tools.

Do this

MONTHLY for machines without the TSC option.

3

Check aluminum air filters on control heat exchanger and at top of spindle motor.

3

Clean exterior surfaces with mild cleaner.

DO NOT

use solvents.

3

Check the hydraulic counterbalance pressure according to the machines specifications.

MONTHLY

3

Inspect way covers for proper operation and lubricate with light oil, if necessary.

3

Dump the oil drain bucket.

3

Place a dab of grease on the outside edge of the Geneva wheel star and guide rails of the tool

changer and run through all tools.

SIX MONTHS

3

Replace coolant and thoroughly clean the coolant tank.

3

Check oil level in gear box by adding oil until it begins dripping from the drain tube.

3

Check all hoses and lubrication lines for cracking.

3

On machines with TSC option, check drawbar height every 6 months or after 1000 hrs of use.

Replace coolant tip if drawbar height is more than .010" out of spec.

ANNUALLY

3

With the air pressure OFF, disassemble and clean the small filter at end of lubricator

(left side of machine).

3

Replace the gearbox oil. Drain the oil from the bottom of the gearbox.

Slowly refill with oil until it overflows at bottom of the gearbox reservoir.

3

Check oil filter and clean out residue at bottom of filter.

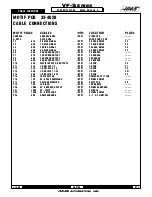

SYSTEM:

WAY LUBE AND PNEUMATICS

TRANSMISSION COOLANT TANK

The following is a list of required regular maintenance for the HAAS VF Series Vertical Machining Centers. Listed are the frequency

of service, capacities, and type of fluids required. These required specifications must be followed in order to keep your machine in

good working order and protect your warranty.

Summary of Contents for VF-SERIES

Page 180: ...1 15 96 96 8100 177 TABLEOFCONTENTS TECHNICAL REFERENCE SERVICE M A N U A L VF SERIES ...

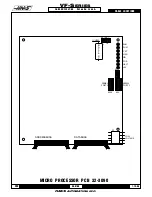

Page 235: ...96 8100 1 15 96 232 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 1 COLUMN ...

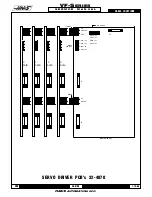

Page 237: ...96 8100 1 15 96 234 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 1 LEADSCREW ...

Page 239: ...96 8100 1 15 96 236 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 3 COLUMN ...

Page 241: ...96 8100 1 15 96 238 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS VF 3 LEADSCREW ...

Page 245: ...96 8100 1 15 96 242 VF SERIES S E R V I C E M A N U A L ASSEMBLY DRAWINGS 3 4 2 1 ...