Installation Manual

Neocean IX1000 Network Storage System

Chapter 2 Installation Preparation

2-4

Long-lasting high humidity in the equipment room leads to poor insulation or even

electricity leakage of insulating materials. In a high-humidity environment, mechanical

performance deterioration, rust and corrosion of some metal parts are more likely to

occur.

If the relative humidity is too low, the captive screws may become loose due to a

contracted insulation washer. Meanwhile, static electricity is likely to be produced in a

dry environment, compromising the circuits of the device. Excessively high temperature

is more harmful to the device.

2.2.3 Cleanness Requirements

Dust is a hazard to the operating safety of the storage appliance. The indoor dust

accumulated on the chassis can cause electrostatic adsorption, which may result in

poor contact of connectors or metal contact points. This happens more frequently when

indoor relative humidity is low, which will not only shorten the service life of the switch,

but also cause equipment failures.

lists the dust concentration limit.

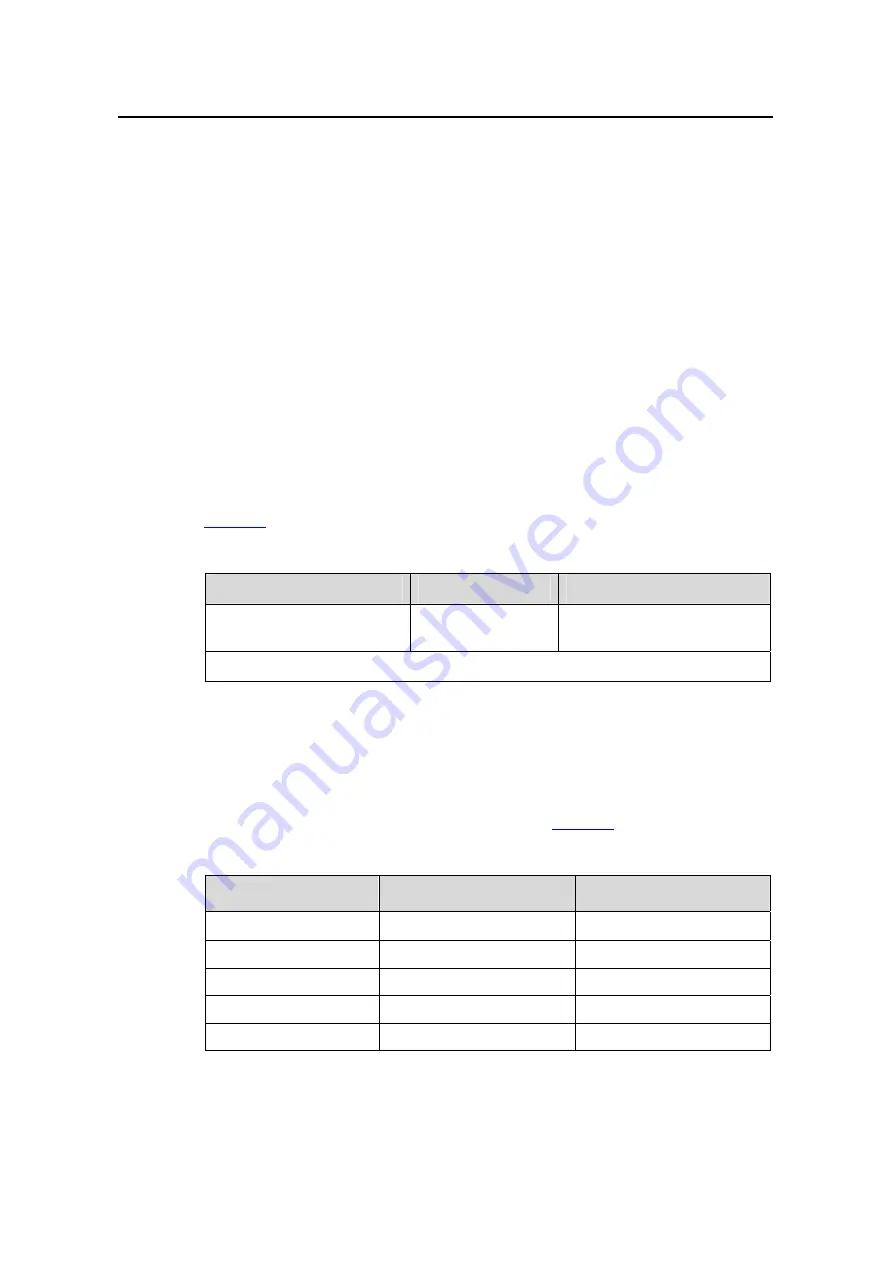

Table 2-3

Limitation on dust content in equipment room

Mechanical active material

Unit

Content

Dust particle

particles/m³

≤

3 x 10

4

(No visible dust on

desk in three days)

Note: Dust particle size

≥

5 µm

Besides the dust specifications, the equipment room should also meet the rigorous

requirements on the contents of salt, acid and sulfide in the air. These harmful gases

can accelerate metal corrosion and the aging of some parts. The equipment should be

protected against harmful gases, such as SO

2

, H

2

S, NO

2

, NH

3

, and Cl

2

. The specific

limitation values of these harmful gases are given in

Table 2-4

Harmful gas limits in an equipment room

Gas

Average (mg/m

3

)

Maximum (mg/m

3

)

SO

2

0.3 1.0

H

2

S 0.1

0.5

NO

2

0.04 0.15

NH

3

1.0 3

Cl

2

0.1 0.3