Model G0854 (Mfd. Since 08/18)

-47-

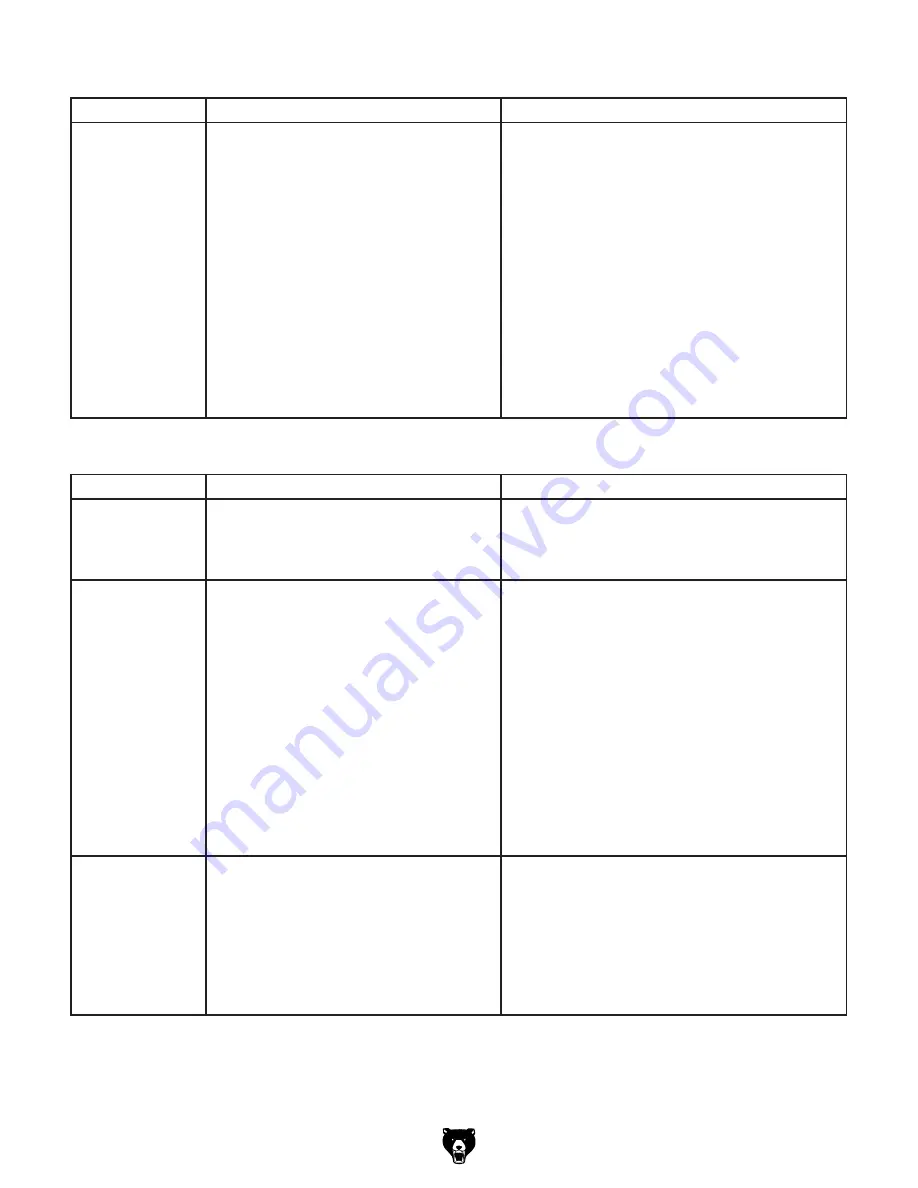

Motor & Electrical (Continued)

Symptom

Possible Cause

Possible Solution

Machine has

vibration or noisy

operation.

1. Motor(s) or components loose.

2. Belt(s) loose or worn.

3. Motor fan(s) rubbing on fan cover.

4. Pulley loose.

5. Machine incorrectly mounted.

6. Motor bearings at fault.

7. Flush trimmer knives at fault.

8. Spindle/arbor bearings at fault.

9. Centrifugal switch is at fault.

10. Motor shaft bent.

1. Inspect/replace damaged bolts/nuts, and retighten

with thread locking fluid.

2. Tension/replace belt (

Page 56).

3. Fix/replace fan cover(s); replace loose/damaged

fan(s).

4. Re-align/replace shaft, pulley set screw, and key.

5. Tighten mounting bolts; relocate/shim machine.

6. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

7. Resharpen/replace knives; set knife alignment/

height correctly (

Page 52).

8. Test by rotating spindle/arbor; rotational grinding/

loose shaft requires bearing replacement.

9. Replace.

10. Test with dial indicator and replace motor.

Glue Spindle

Symptom

Possible Cause

Possible Solution

Glue spindle does

not rotate.

1. Motor does not run.

2. Too much grease added to glue spindle.

3. Gear connection shaft stripped/broken.

4. Gear connection shaft stuck.

1. Refer to

Page 46.

2. Loosen pressure-relief set screw.

3. Inspect/replace gear connection shaft.

4. Adjust motor reducer connection plate.

Glue spindle does

not dispense

enough glue.

1. Glue flow out of adjustment.

2. Glue not fully melted, temperature setting

too low.

3. Glue spindle not making full contact with

workpiece.

4. Glue not fully melted, heater rods not

working correctly.

5. Obstruction in glue shaft.

6. Burnt glue in glue spindle.

7. Glue pot thermometer not accurate.

1. Adjust glue flow (

Page 51).

2. Adjust glue pot temperature according to glue

manufacturer's directions; confirm glue temperature

using laser thermometer.

3. Adjust glue spindle (

Page 36).

4. Inspect heater rod connections; tighten if necessary.

Test heater rod amperage (top: 315W, 1.0A; lower

large: 250W, 0.9A; lower small: 160W, 0.6A);

replace if necessary.

5. Remove obstruction from glue shaft.

6. Remove burnt glue from glue spindle.

7. Inspect thermocouple connections and wires for

damage/wear; repair/replace if necessary.

Glue not fully melted

in glue pot.

1. Glue pot still heating.

2. Glue pot temperature is set too low.

3. Heater rods at fault.

1. Wait until glue reaches working temperature.

2. Adjust glue pot temperature according to glue

manufacturer's directions; confirm glue temperature

using laser thermometer.

3. Inspect heater rod connections; tighten if necessary.

Test heater rod amperage (top: 315W, 1.0A; lower

large: 250W, 0.9A; lower small: 160W, 0.6A);

replace if necessary.

Summary of Contents for G0854

Page 96: ......