FC3100-60 Service Manual

P/N53802-031T Rev. A

7 - 1

7. TROUBLESHOOTING

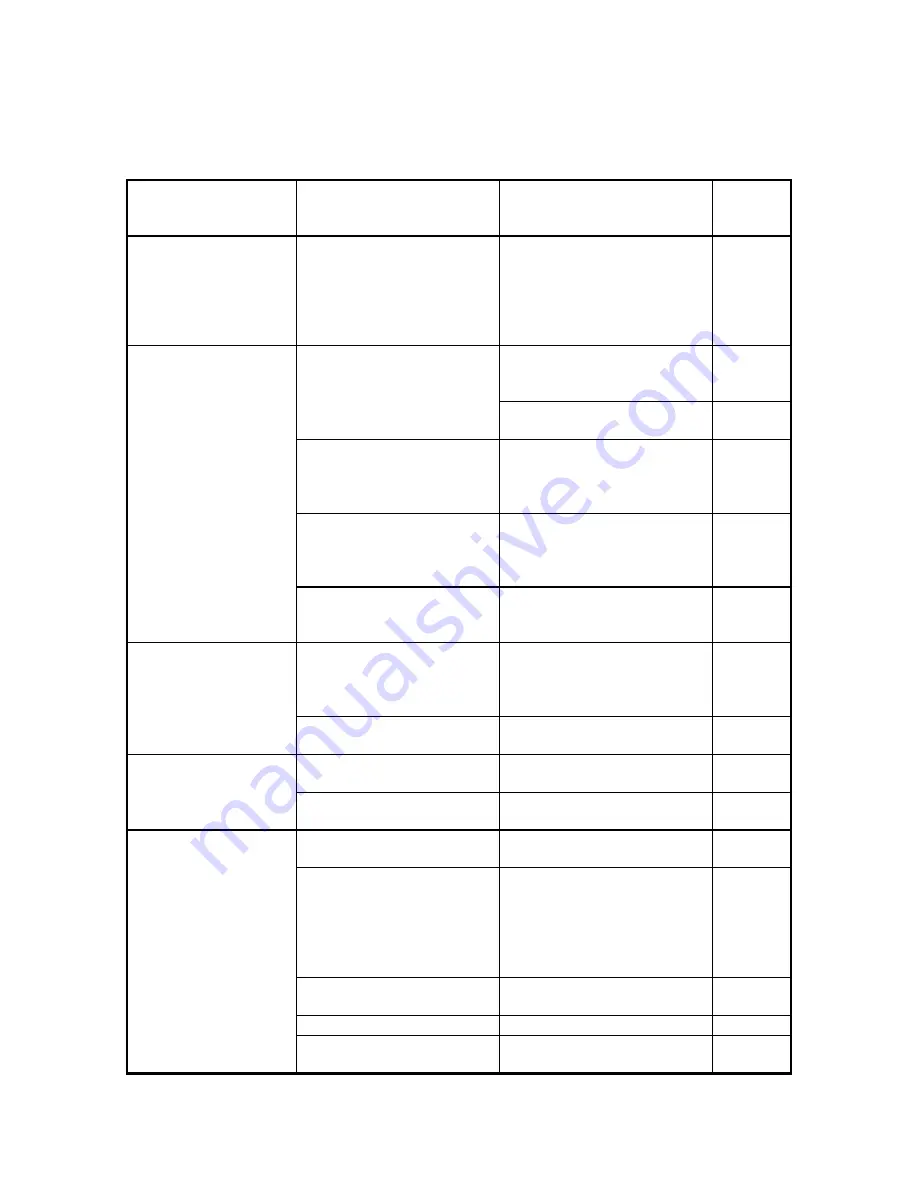

7.1 The Cutting Results are Unsatisfactory

Problem

Cause

Solution

See User's

Manual

section:

•

The cut corners are

rounded or too pointed.

•

The CUTTER OFFSET is

incompatible with the blade

type being used.

•

Adjust the CUTTER OFFSET

value:

* If too low, corners become

rounded.

* If too high, corners are too

pointed.

4.5

4.8

•

The cut line starts out

crooked.

•

The blade mounted in the

holder does not rotate

smoothly.

•

Grease the blade and holder.

3.3

•

Remove any foreign matter

inside the pen holder.

•

The Offset Cut Pressure is

too low.

•

Raise the Offset Cut Pressure

setting (the Offset Cut Pressure

is separate from the cutting

FORCE).

5.11

•

With the 0.9 mm cutter pen

(blue blade adjustment knob),

the spring has come loose

from the blade.

•

Replace the blade with a new

one that has a spring.

3.3

•

With the 1.5 mm cutter pen

(red blade adjustment knob),

the blade has fallen out.

•

Grease the blade and holder

(B).

3.3

•

The blade skips and

does not completely cut

lines that should be

solid.

•

The blade is extended too

far.

•

Adjust the blade length.

3.4

•

Solid lines are not cut

at a constant depth.

•

The cutting SPEED is too

high.

•

Lower the SPEED setting.

4.5

•

Coarse resolution of

curved lines.

•

The software's resolution

setting is too low.

•

Adjust the software's

resolution setting.

•

The blade offset angle is too

low.

•

Raise the blade offset angle.

5.12

•

The film curls up at the

corners.

•

The blade is extended too

far.

•

Adjust the blade length.

3.4

•

The film curls up when

cutting small

characters.

•

The CUTTER OFFSET is

incompatible with the blade

type being used.

•

Adjust the CUTTER OFFSET

value:

* If too low, corners become

rounded.

* If too high, corners are too

pointed.

4.5

4.8

•

The cutting SPEED is too

high.

•

Lower the SPEED setting.

4.5

•

The blade is dull.

•

Replace the blade.

3.3

•

The QUALITY setting is too

high.

•

Lower the QUALITY setting.

4.5

Summary of Contents for CUTTING PRO FC3100-60

Page 10: ...FC3100 60 Service Manual P N53802 031T Rev A 1 6 FC3100 60 with Stand Option Unit mm...

Page 18: ...FC3100 60 Service Manual P N53802 031T Rev A 2 8 Sample printout by the CONDITION function...

Page 113: ...FC3100 60 Service Manual P N53802 031T Rev A 5 17 CONDITION 4...

Page 131: ...FC3100 60 Service Manual P N53802 031T Rev A 8 2 Mainframe...

Page 133: ...FC3100 60 Service Manual P N53802 031T Rev A 8 4 Y Drive Section...

Page 135: ...FC3100 60 Service Manual P N53802 031T Rev A 8 6 X Drive Section...

Page 137: ...FC3100 60 Service Manual P N53802 031T Rev A 8 8 Push Roller Arm and Y Rail Section...

Page 140: ...FC3100 60 Service Manual P N53802 031T Rev A 8 11 Pen Block and Y Slider Section...

Page 142: ...FC3100 60 Service Manual P N53802 031T Rev A 8 13 Chassis Section...

Page 144: ...FC3100 60 Service Manual P N53802 031T Rev A 8 15 Film Stocker Section...

Page 147: ...FC3100 60 Service Manual P N53802 031T Rev A 8 18 Stand and Media Basket Option...

Page 149: ...FC3100 60 Service Manual P N53802 031T Rev A 8 20 Pouncing Tool Option...

Page 151: ...FC3100 60 Service Manual P N53802 031T Rev A 9 2 Wiring Diagram...

Page 153: ...FC3100 60 Service Manual P N53802 031T Rev A 9 4 Main Board Wiring Diagram...

Page 154: ...FC3100 60 Service Manual P N53802 031T Rev A 9 5 Main Board Interface Section...

Page 155: ...FC3100 60 Service Manual P N53802 031T Rev A 9 6 Main Board CPU Section...

Page 156: ...FC3100 60 Service Manual P N53802 031T Rev A 9 7 Main Board Memory Section...

Page 157: ...FC3100 60 Service Manual P N53802 031T Rev A 9 8 Main Board 1MB Buffer Section...

Page 158: ...FC3100 60 Service Manual P N53802 031T Rev A 9 9 Main Board GRC1504 Section...

Page 159: ...FC3100 60 Service Manual P N53802 031T Rev A 9 10 Main Board Clock Section...

Page 160: ...FC3100 60 Service Manual P N53802 031T Rev A 9 11 Main Board Reset Section...

Page 161: ...FC3100 60 Service Manual P N53802 031T Rev A 9 12 Main Board Driver Section Diagram...

Page 162: ...FC3100 60 Service Manual P N53802 031T Rev A 9 13 Main Board Motor DAC Section...

Page 163: ...FC3100 60 Service Manual P N53802 031T Rev A 9 14 Main Board Motor Drive Section...

Page 164: ...FC3100 60 Service Manual P N53802 031T Rev A 9 15 Main Board A D Section...

Page 165: ...FC3100 60 Service Manual P N53802 031T Rev A 9 16 Main Board Pen DAC Section...

Page 166: ...FC3100 60 Service Manual P N53802 031T Rev A 9 17 Main Board Pen Drive Section...

Page 167: ...FC3100 60 Service Manual P N53802 031T Rev A 9 18 Main Board Input and Output Section...

Page 168: ...FC3100 60 Service Manual P N53802 031T Rev A 9 19 Main Board Connector Section 1...

Page 169: ...FC3100 60 Service Manual P N53802 031T Rev A 9 20 Main Board Connector Section 2...

Page 171: ...FC3100 60 Service Manual P N53802 031T Rev A 9 22 Interconnection Board...

Page 173: ...FC3100 60 Service Manual P N53802 031T Rev A 9 24 Pen Board...

Page 175: ...FC3100 60 Service Manual P N53802 031T Rev A 9 26 Sheet Switch Control Panel...