115

232001840G(08)

NOTE

This instruction is a simple example for general use. There are many tips and tricks to achieve a

good engraving quality. It takes a lot of practice and experience to achieve a good engraving

quality. Different picture may need different modifications and different material may need

different parameters.

Summary of Contents for LaserPro C180II

Page 1: ...232001840G 08 ...

Page 20: ...20 4 Place the machine into the package box 5 Cover the lid and tighten by rope ...

Page 29: ...232001840G 08 ...

Page 34: ...232001840G 06 ...

Page 35: ...232001840G 08 ...

Page 107: ...107 232001840G 08 ...

Page 109: ...109 232001840G 08 ...

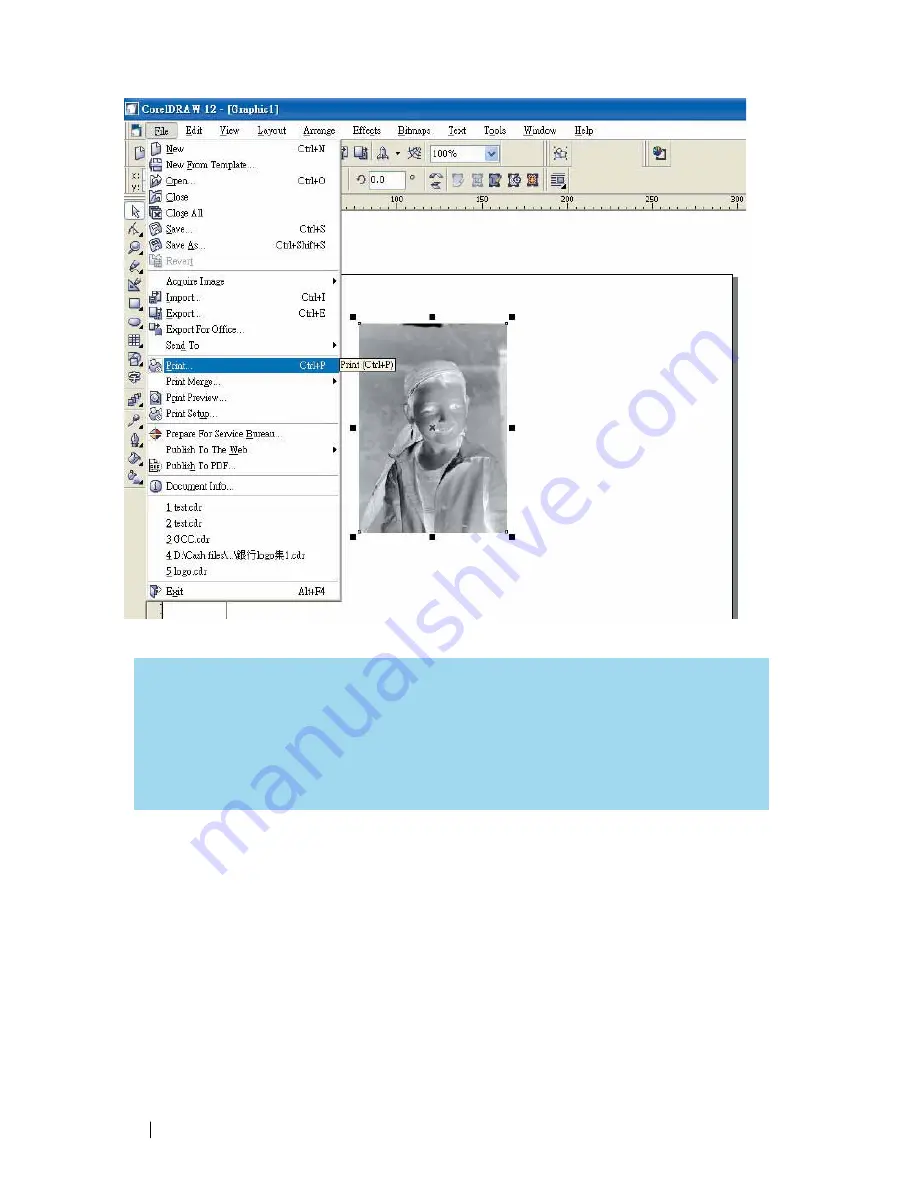

Page 114: ...114 232001840G 08 8 Now you are ready to output the modified image by clicking File Print ...

Page 137: ...137 232001840G 08 Chapter 9 Basic Troubleshooting ...

Page 139: ...139 232001840G 08 Chapter 10 Appendix Glossary LaserPro C180II Series Specification Sheet ...