C1 Controllers and Transmitters

Instruction Manual

September 2009

17

A2202

−

3 / IL

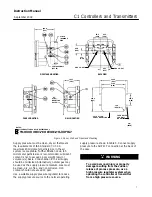

PROPORTIONAL BAND KNOB SETTING

DIFFERENTIAL GAP (PERCENT OF ELEMENT RANGE)

Figure 10. Differential Gap Adjustment for Differential Gap

Controllers

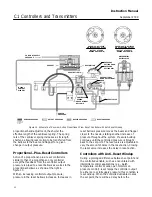

pressure with rising process pressure (direct

−

acting

controllers) or with falling process pressure

(reverse

−

acting controllers).

Adjustment: Proportional Band

The proportional band adjustment shown in figure 4

determines the width of the differential gap. The

width of the gap is the difference between the

process pressures at which the controller output will

switch from zero to full supply pressure, or from full

supply pressure to zero. The relationship between

the proportional band dial setting and the differential

gap is shown in figure 10.

Calibration: Differential Gap Controllers

The output of each controller is checked at the

factory before the unit is shipped. Before placing the

controller in control of a process loop, check to verify

that the controller is calibrated correctly for the

application. The controller must be connected open

loop (Open loop: The controller output pressure

changes must be dead ended into a pressure

gauge).

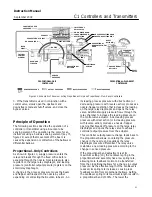

1. Temporarily convert the differential gap controller

to proportional

−

only controller by disconnecting the

proportional tubing (key 25, figure 16) from the

mounting base. Reinstall the tubing into the other

connection in the mounting base. Remove the

proportional band assembly and invert it as shown in

figure 16. Do not invert the reversing block (key 37,

figure 16).

2. Temporarily invert the proportional band

assembly (refer to figure 18):

a. Turn the proportional band assembly (key 73)

to 10.

b. Unscrew the spring adjustor (key 65),

removing the bias spring (key 70) and washers

(key 62) with it.

c. Unclip the lock spring (key 72). Remove the

indicator scale (key 69) and proportional band

adjustment knob (key 73).

d. Remove the gain adjustment bar (key 63). Flip

it over so it attaches to the opposite side of the

cantilever spring (key 8) as shown in figure 16

and screw it back down.

e. Flip over the indicator scale (key 69); install it

and the proportional band adjustment knob

(key 73) as a unit. Snap in the lock spring

(key 72).

f. Tighten down the spring adjustor (key 65) with

the bias spring (key 70) and washers (key 62)

until it stops against the gain adjustment bar

(key 63).

g. Turn the proportional band adjustment knob to

the 10 setting. If it cannot be turned to the 10

setting, loosen the spring adjustor (key 65).

3. Calibrate using the calibration procedure for

proportional

−

only controllers found on page 10 of

this manual.

4. When calibration is complete, return the tubing

(key 25) and the proportional band assembly to their

original locations and continue on with step 5 of this

procedure.

Note

After reinstalling the tubing (key 25)

and proportional band assembly a

slight offset of the output pressure will

be noticed due to a combination of

switching from the proportional

bellows to the reset bellows and the

repositioning of the cantilever spring.

Performing step 6b below adjusts for

this offset.

5. Refer to figure 10 to determine the proportional

band dial setting required for the desired differential

gap.

For example, assume that a 0 to 100 psig sensing

element is being used and the controller is to switch

from zero to full supply pressure at a process