C1 Controllers and Transmitters

Instruction Manual

September 2009

12

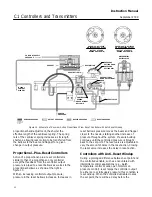

adjuster screws while holding the

calibration adjuster in place. Then

move the calibration adjuster slightly

in the required direction by hand or

using a screwdriver. Verify proper

nozzle

−

to

−

flapper alignment and hold

the calibration adjuster in place while

tightening both adjustment screws.

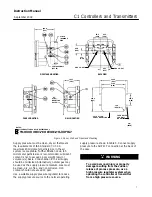

9. If the output is not between 0.6 and 0.7 bar (8

and 10 psig), adjust the controller span by loosening

the two adjusting screws (key 48) and moving the

calibration adjuster (key 36) a small distance as

indicated in figure 6.

10. Repeat steps 4 through 9 until no further

adjustment is necessary.

11. Proceed to the startup procedure for

proportional controllers.

Startup: Proportional

−

Only Controllers

(General Tuning Guidelines)

Calibrate the controller prior to this procedure.

1. Be sure that the supply pressure regulator is

delivering the proper supply pressure to the

controller.

2. Rotate the pressure setting knob to the desired

set point.

3. Set the proportional band adjustment to 100

percent for fast processes (example: liquid pressure

or liquid flow). For slow processes (example:

temperature), calculate the percentage from the

equation below:

For a slow process, determine the initial proportional

band setting in percent from the following equation:

2

Allowable Overshoot

Pressure Span

100%

+

P.B.

For example:

2

0.14 bar

2.1 bar

100%

^

13%

2

2 psig

30 psig

100%

^

13%

(

)

1.3 proportional band setting

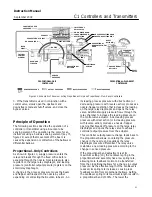

4. Proportional Action

Disturb the system by tapping the flapper lightly or

change the set point a small amount and check for

system cycling. If the system does not cycle then

lower the proportional band (raising the gain) and

disturb the system again. Continue this procedure

until the system cycles. At that point, double the

proportional band setting.

Note

Proportional band adjustment affects

the set point. Proportional

−

only

controllers will show some offset from

set point depending upon proportional

band setting and process demand.

After adjusting the proportional band,

re

−

zero by carefully rotating the nozzle

(key 54) until the steady

−

state process

pressure equals the pressure setting

dial reading.

This tuning procedure may be too conservative for

some systems. The recommended proportional band

setting should be checked for stability by introducing

a disturbance and monitoring the process.