C1 Controllers and Transmitters

Instruction Manual

September 2009

9

line, adequate ventilation, and

necessary safety measures should be

used to prevent the accumulation of

flammable or hazardous gas. However,

a remote vent pipe alone cannot be

relied upon to remove all flammable

and hazardous gas. Vent line piping

should comply with local and regional

codes, and should be be as short as

possible with adequate inside diameter

and few bends to reduce case

pressure buildup.

CAUTION

When installing a remote vent pipe,

take care not to overtighten the pipe in

the vent connection. Excessive torque

will damage the threads in the

connection.

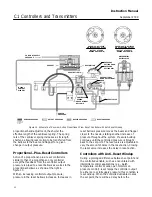

The vent assembly (key 28, figure 2) or the end of a

remote vent pipe must be protected against the

entrance of all foreign matter that could plug the

vent. Use 13 mm (1/2

−

inch) pipe for the remote vent

pipe, if one is required. Check the vent periodically

to be certain it has not become plugged.

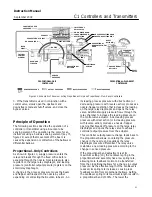

Controller Operation

Proportional

−

Only Controllers

This section describes the adjustments and

procedures for calibration and startup. Adjustment

locations are shown in figure 4 unless otherwise

specified. All adjustments must be made with the

cover open. When the adjustments and calibration

procedures are complete, close and latch the cover.

To better understand the adjustments and overall

operation of the controller, refer to the Principle of

Operation section in this manual for

proportional

−

only controllers. Refer also to the

schematic diagram in figure 13.

Adjustments

Adjustment: Set Point

Adjust the pressure setting knob by turning the knob

clockwise to increase the set point and

counterclockwise to decrease the set point. Note

that the dial setting and actual process pressure may

vary significantly, especially with a wide proportional

band setting.

GE33946

−

A

SUPPLY PRESSURE

REGULATOR

SUPPLY PRESSURE

REGULATOR

TYPICAL ROTARY ACTUATOR

TYPICAL SLIDING STEM ACTUATOR

GE33947

−

A

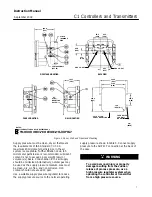

Figure 3. Actuator Mounting

Adjustment: Proportional Band

To adjust the proportional band, rotate the

proportional band adjustment knob to the desired

value.

The proportional band adjustment determines the

amount of change in controlled pressure required to

cause the control valve to stroke fully. It may be

adjusted from 2 to 100 percent for 0.2 to 1.0 bar (3

to 15 psig) or 4 to 100 percent for 0.4 to 2.0 bar (6 to

30 psig) of the nominal sensing element pressure

rating.